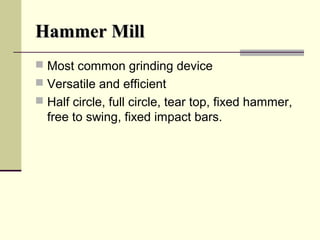

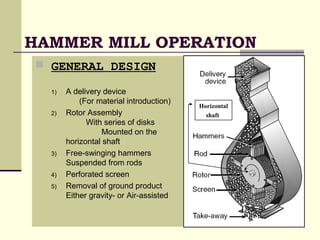

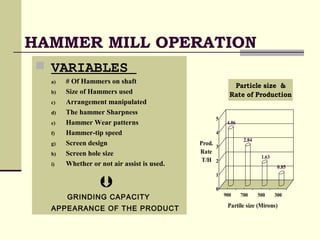

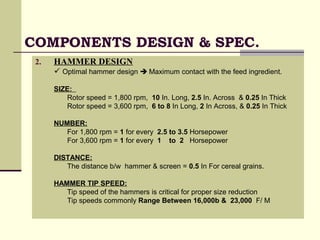

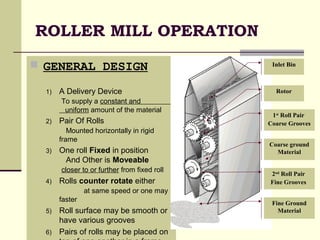

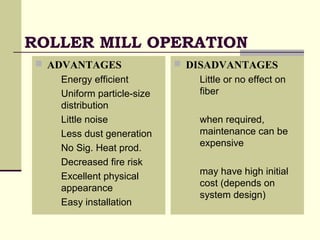

This document discusses feed manufacturing processes, with a focus on grinding methods. It describes the functions of hammer mills and roller mills. Hammer mills are the most common grinding device and use hammers on a rotor to reduce particle size through impact. Roller mills use compression and shearing forces between counter-rotating rolls. The document provides details on the components, operation, advantages, and disadvantages of each type of grinder to optimize particle size for animal feed applications.

![PARTICLE SIZE

EFFECT ON NUTRIENT COMPOSITION

CORN Different fractions based on Particle Size

have little or no effect on nutrient composition. [ Nir et al. 1994 ]

CONCLUSIONS

In pelleted or crumbled diets

little effect on live performance,

uniformity of nutrient content of feed

Or the pellet quality produced

If grains are to be incorporated into mash,

Finer particle sizes (less than 600 µ GMD) should be avoided.

Producers should adjust grinding size depending the form of diet to

be fed ( Mash / Pellet) using hammer mill and roller mill grinding.](https://image.slidesharecdn.com/feedmanufacturing-grinding-160507135145/85/Feed-manufacturing-grinding-11-320.jpg)