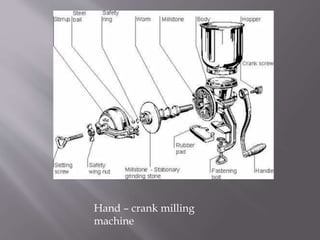

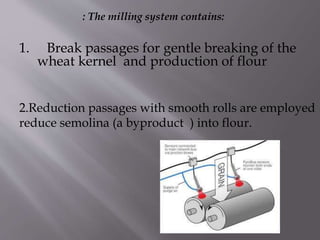

Flour mills grind grain, such as wheat, into flour through a series of processes. Traditionally, mills used stone wheels to grind grain, but modern automated mills use steel wheels and are computer controlled. The milling process involves cleaning and storing wheat, grinding it to separate the flour from bran and skins, and further storing and packaging the milled products. Milling breaks wheat kernels down through multiple passages that gently break and further reduce the material to produce flour.