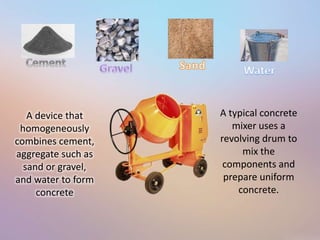

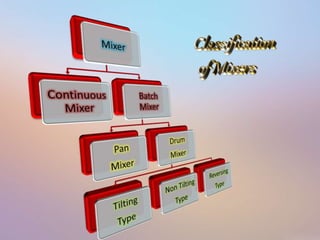

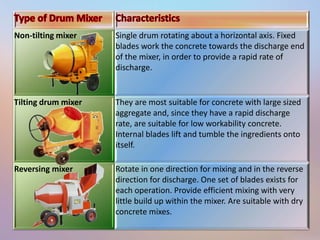

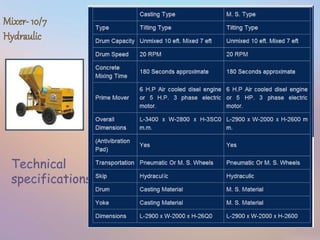

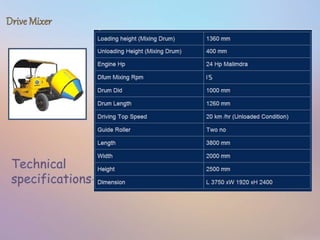

The document describes different types of concrete mixers, including non-tilting, tilting, and reversing mixers, highlighting their designs and suitable applications based on concrete types. It also provides specifications for various mixer models, including capacity and output. Additionally, it explains the function of transit mixers, which transport and mix concrete, maintaining its liquid state during delivery.