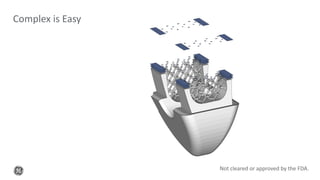

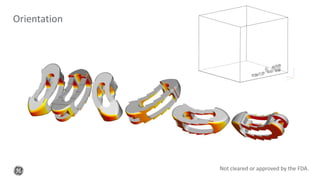

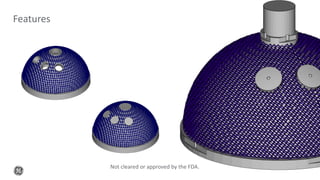

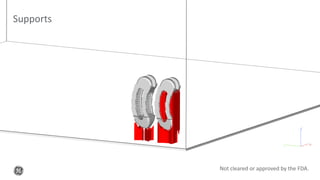

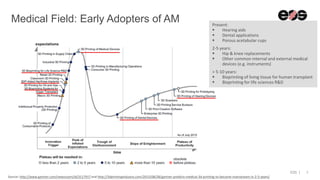

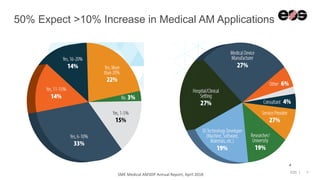

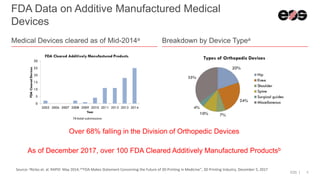

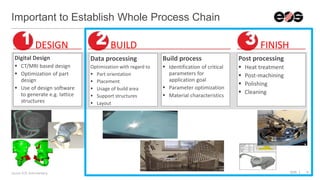

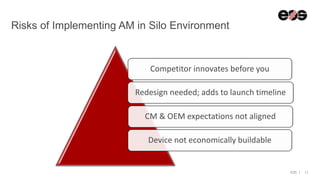

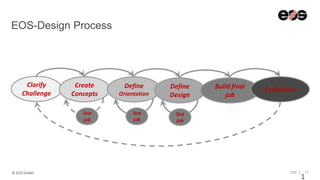

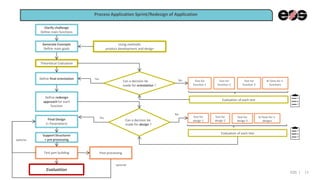

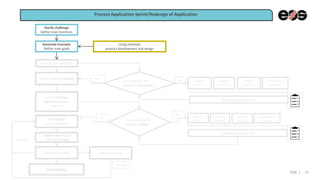

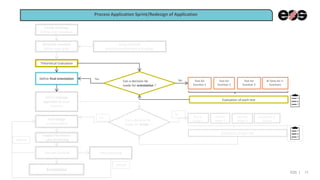

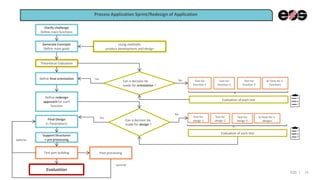

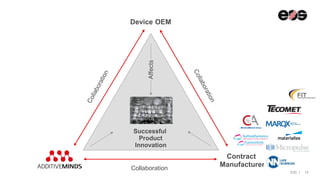

The document outlines a presentation by Dr. Maria Pettersson on optimizing the design stage of additive manufacturing in the orthopedic industry, emphasizing efficient clinical outcomes and post-processing. It covers critical aspects such as design orientation, supports, and collaboration along the manufacturing chain. The presentation also notes the rise of medical applications and FDA-cleared devices in additive manufacturing, highlighting its growing significance in the industry.