1. Water is essential for human survival but is often contaminated.

2. Water sources include surface water and groundwater, with varying levels of physical, chemical, and biological impurities depending on the source.

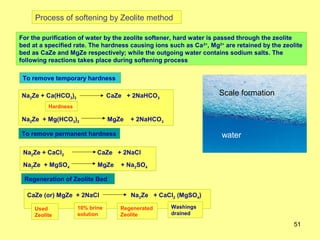

3. Hard water contains high levels of calcium and magnesium ions which can cause soap scum, clog pipes and boilers, and is classified as temporary or permanent hardness. Preventing scale formation in boilers is important to improve efficiency and avoid accidents.

![pH

• pH a measure of hydrogen ion activity is used to

express the intensity of acidic or alkaline condition of a

solution.

• The pH scale runs to 0 from 14 with 0 representing

maximum acidity and 14 maximum basicity

pH = -log [H+]

8](https://image.slidesharecdn.com/unit1watertechnology-121111071552-phpapp01/85/Unit-1-water_technology-8-320.jpg)

![3. Calgon conditioning

Na 2 [Na 4 (PO 3 ) 6 2Na+ +

[Na 4 P 6 O 18 ] 2-

Calgon – sodium

hexa meta

phosphate

2CaSO 4 (Boiler water) + [Na 4 P 6 O 18 ] 2- [Ca 2 P 6 O 18 ] 2- + 2Na 2 SO 4

Calcium

Soluble complex ion

sulfate

of calcium - can be

removed easily

Calgon tablets are used in the cleaning of washing machine

drums

28](https://image.slidesharecdn.com/unit1watertechnology-121111071552-phpapp01/85/Unit-1-water_technology-28-320.jpg)

![IV. Boiler

corrosion

Degradation or destruction of boiler materials (Fe) due to the

chemical or electrochemical attack of dissolved gases or salts is

called boiler corrosion

Boiler corrosion is of three types

1. Corrosion due to dissolved O 2

2. Corrosion due to dissolved CO 2

3. Corrosion due to acids formed by dissolved

salts

1. Corrosion due to dissolved oxygen

(DO)

2 Fe + 2 H2O + O2 2 Fe(OH)2

4 Fe(OH)2 + O2 2 [Fe2O3.2H2O]

Ferrous Rust

hydroxide

31](https://image.slidesharecdn.com/unit1watertechnology-121111071552-phpapp01/85/Unit-1-water_technology-31-320.jpg)