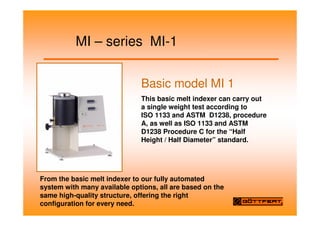

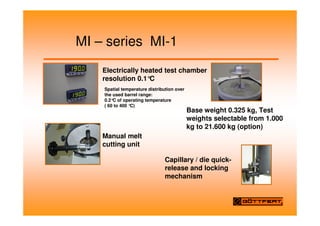

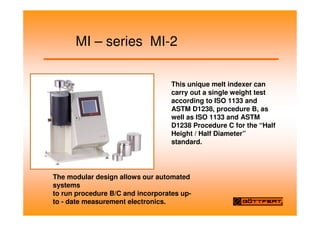

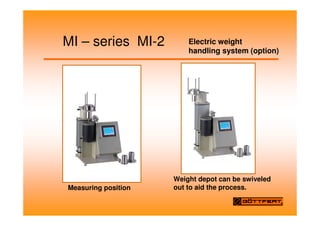

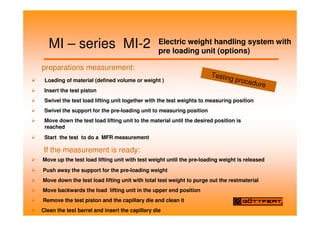

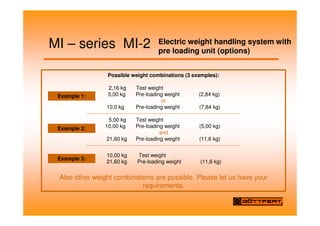

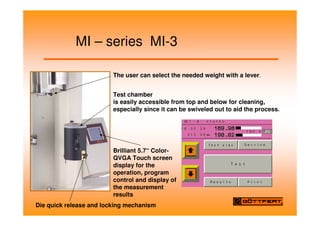

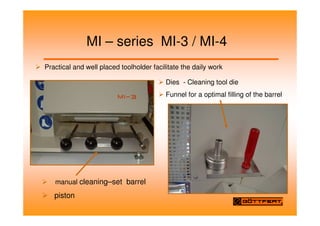

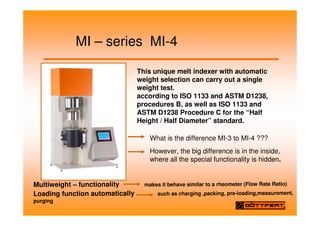

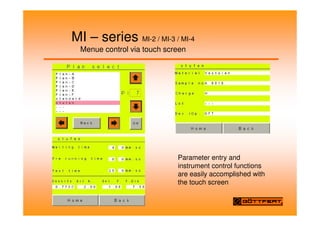

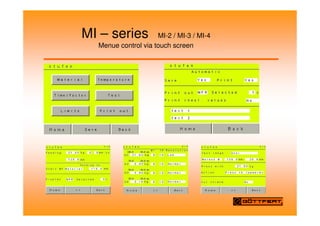

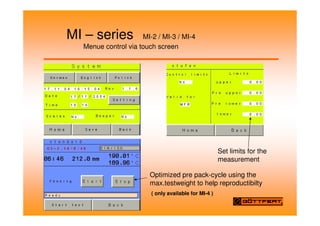

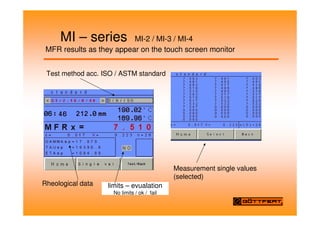

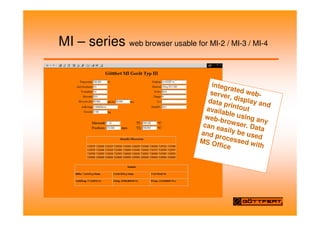

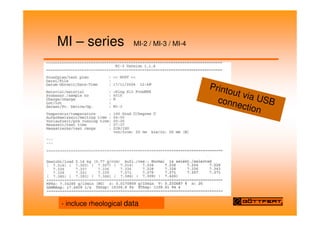

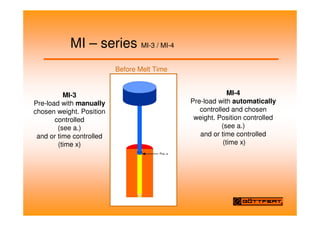

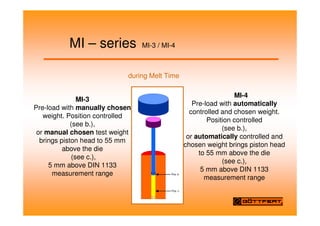

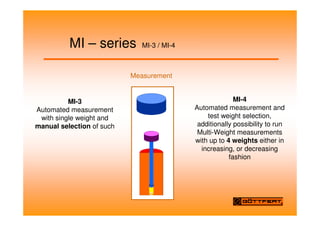

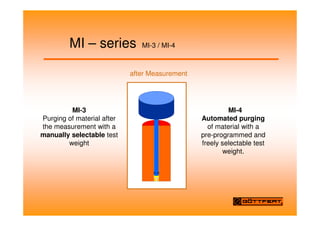

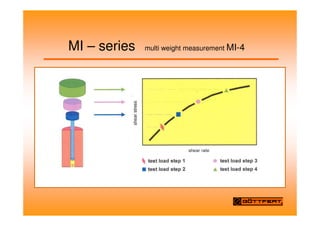

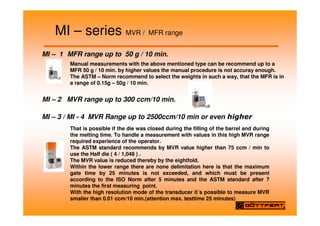

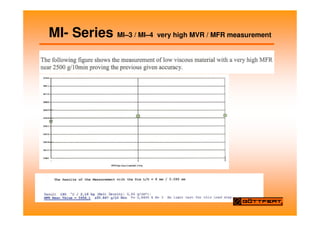

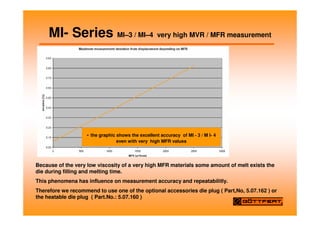

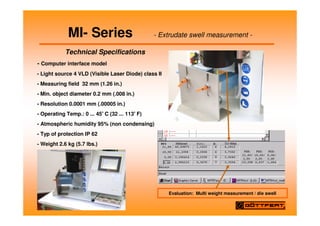

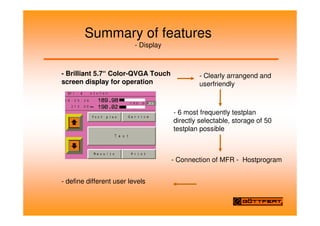

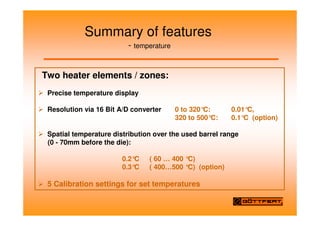

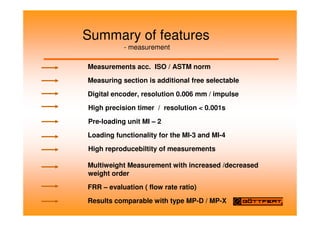

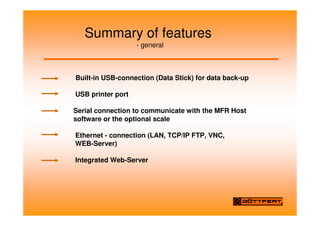

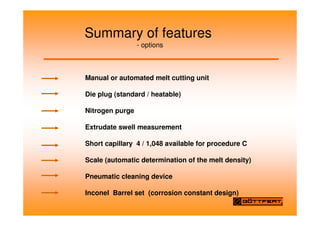

The document describes the MI series of automated extrusion plastometers and melt indexers from M. Ackermann. It details the features of four models - the MI-1, MI-2, MI-3, and MI-4. The MI-1 is a basic single-weight tester, while the MI-2, MI-3, and MI-4 have increased automation and functionality including automatic weight selection, multi-weight testing, and improved loading and packing features. All models meet ISO and ASTM standards for melt flow rate testing and are designed for reliability, precision, and ease-of-use.