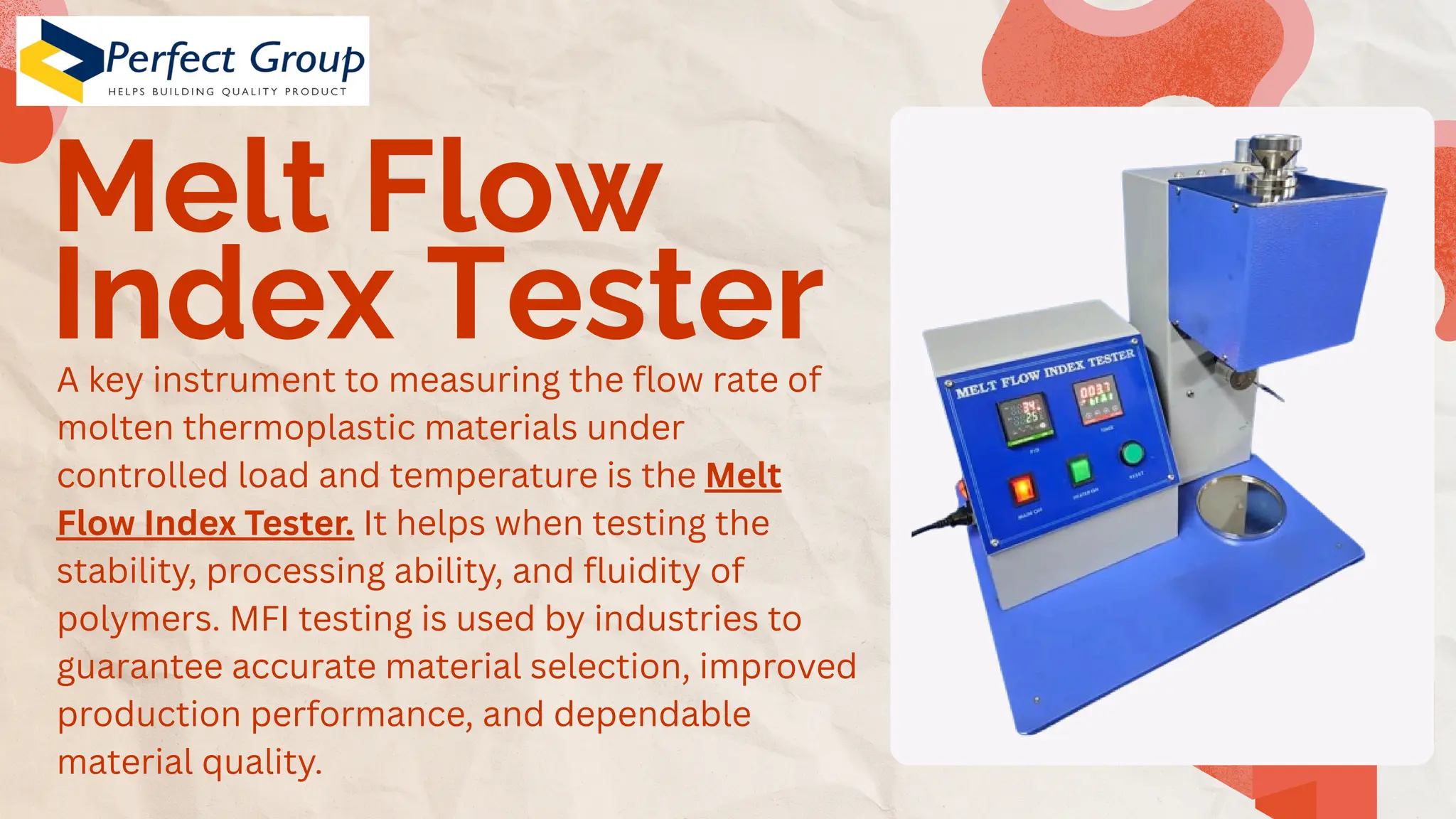

The Melt Flow Index Tester, common in the plastic industry, measures the flow characteristics of molten polymers. It supports manufacturers when analyzing process stability and identifying perfect material grades for various operations. Accurate readings simplify quality checks and guarantee trustworthy, high-performance polymer products.