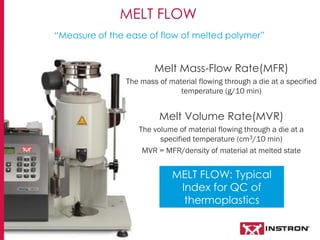

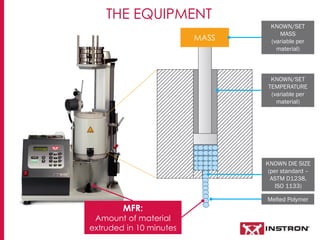

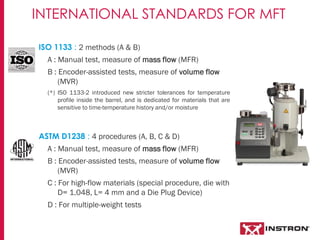

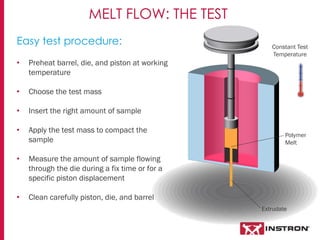

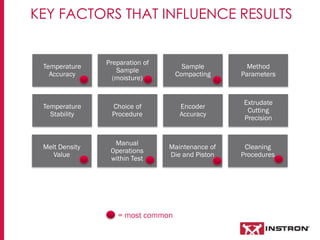

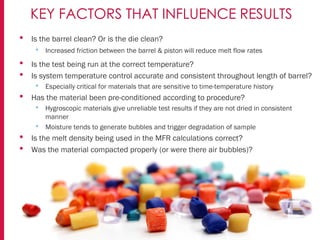

This document provides an overview of melt flow testing based on ISO 1133 and ASTM D1238 standards. Melt flow testing measures the mass or volume of melted polymer that flows through a die in 10 minutes at a specified temperature. It is commonly used for quality control of thermoplastics to verify materials, check quality, compare new materials, and predict polymer processing behavior. Key factors that can influence melt flow results include temperature accuracy and stability, sample preparation and compaction, density value used, cleaning procedures, and manual versus automatic test operations.