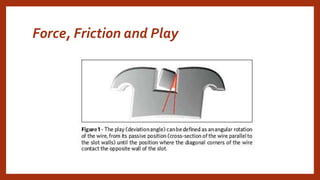

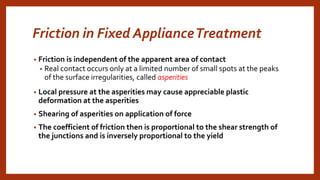

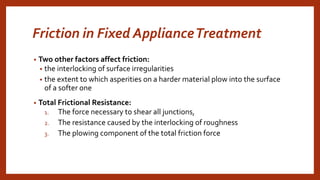

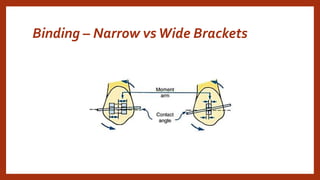

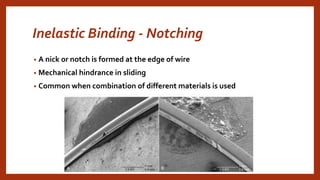

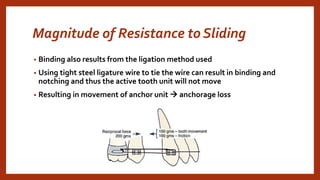

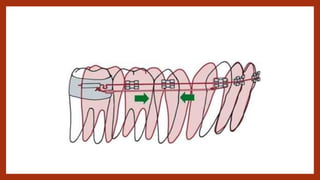

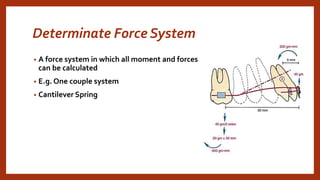

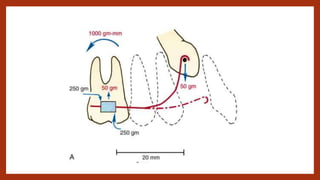

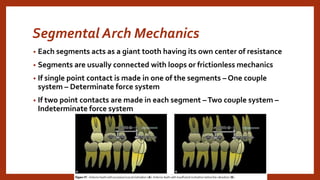

This document discusses mechanical aspects of anchorage control in orthodontic treatment. It covers topics like friction, binding, surface qualities of wires and brackets, and determinate versus indeterminate force systems. Regarding friction, it explains how factors like surface roughness, reactivity and hardness affect friction. It also discusses how binding between brackets and wires increases resistance to sliding. The document concludes by outlining different methods that can be used to control anchorage, including reinforcement of anchorage units and subdivision of tooth movements.