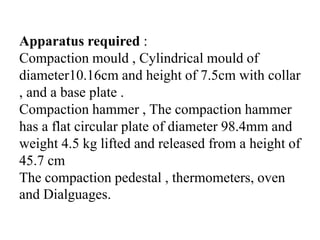

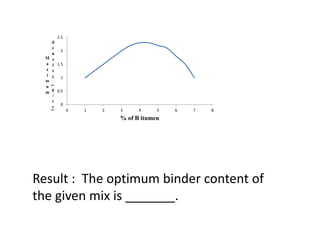

The document describes the Marshall method of determining the optimum binder content for a bituminous mix design. Aggregates and binder are heated and mixed to different binder contents. Specimens are compacted with blows from a hammer and tested for properties like flow value, stability, and density. Graphs are made plotting these properties against the varying binder contents. The optimum binder content is determined as the percentage where the graphs show highest stability and density and lowest flow value.