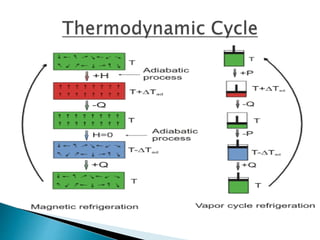

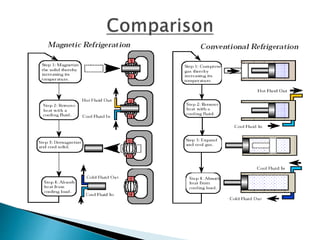

This document summarizes magnetic refrigeration technology. It discusses how magnetic refrigeration uses the magnetocaloric effect to produce cooling through applying and removing a magnetic field to magnetic materials. The document outlines the basic thermodynamic cycle of magnetic refrigeration and compares it to a vapor compression cycle. It also discusses some promising magnetocaloric materials and challenges to overcome like reducing costs and improving efficiency to enable widespread commercial applications of magnetic refrigeration.