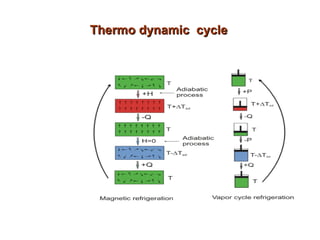

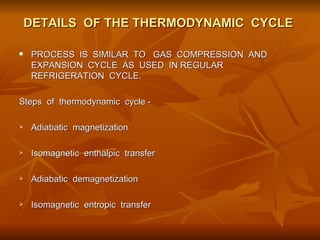

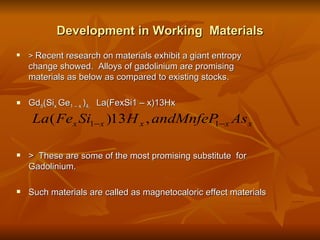

The document summarizes Ganesh Pralhad Bharambe's seminar on magnetic refrigeration presented under the guidance of Prof. A. M. Patil. It discusses the basic principles of magnetic refrigeration, the thermodynamic cycle involved, suitable working materials including developments in materials science, and applications of the technology.