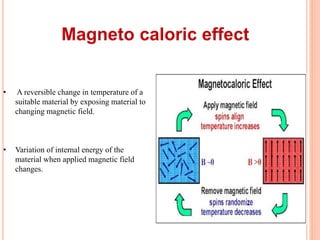

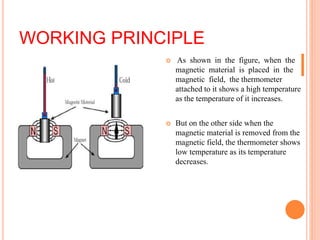

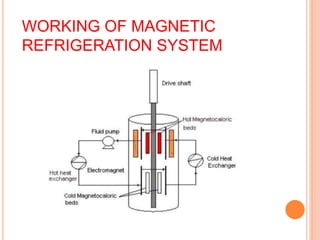

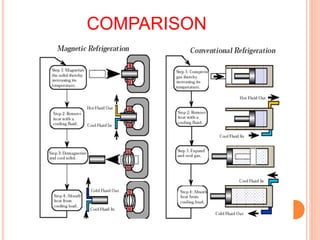

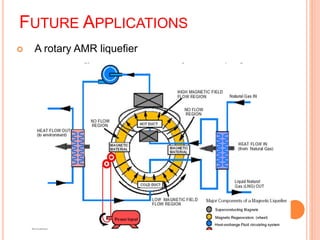

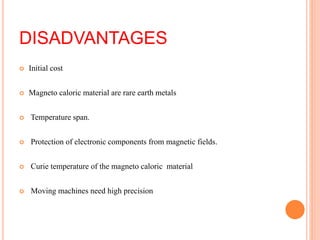

This document discusses magnetic refrigeration, including its working principle, components, advantages, and current state of development. Magnetic refrigeration uses the magnetocaloric effect and works by applying and removing a magnetic field to materials to remove and release heat from target systems. Its potential advantages include higher efficiency and reliability compared to vapor compression refrigeration, without using ozone-depleting refrigerants. However, magnetic refrigeration remains under development due to challenges like initial costs and limited temperature ranges of magnetocaloric materials.

![CONCLUSION

No hazardous chemicals used [Environment friendly]

Improved efficiency about 25% increase

Larger temperature span

Permanent magnet need to produce strong magnetic field over 10tesla

Some thermal and hysteresis problem

WHY IS IT STILL UNDER CONSTRUCTION?](https://image.slidesharecdn.com/magneticref-170720191733/85/seminar-on-Magnetic-Refrigeration-Solid-refrigerant-22-320.jpg)