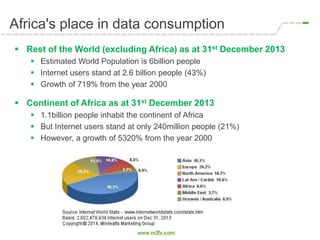

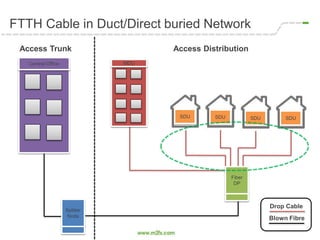

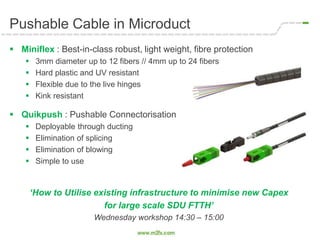

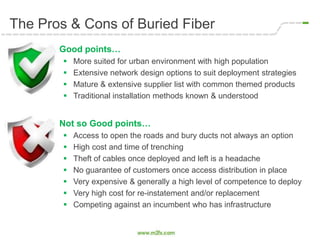

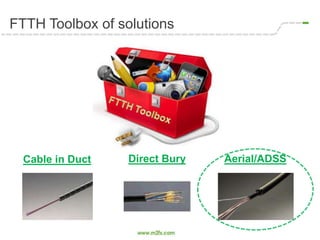

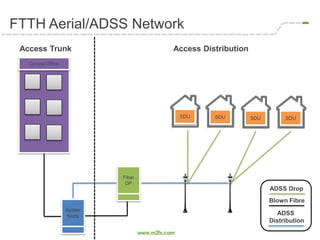

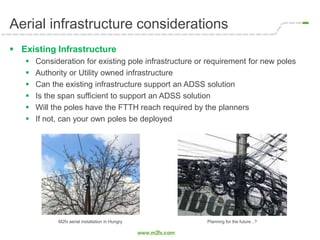

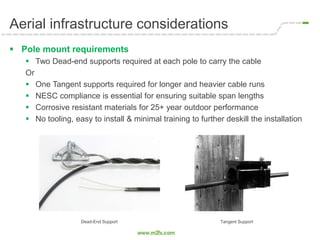

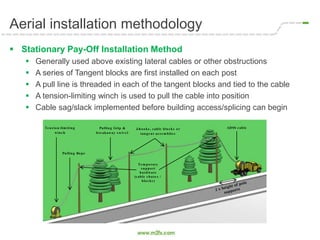

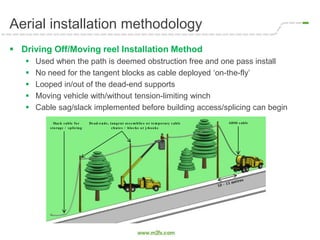

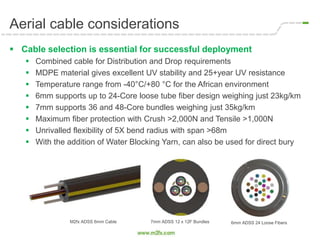

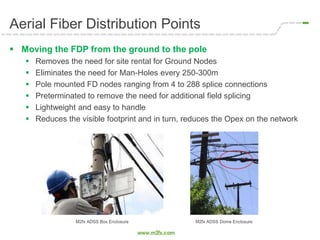

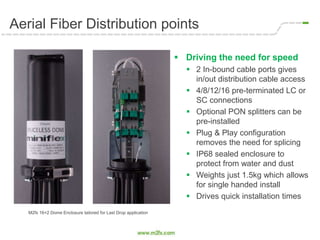

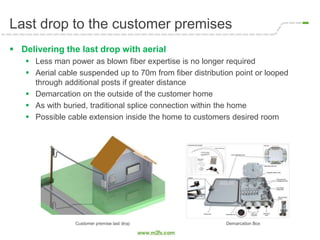

The document discusses alternative infrastructure deployment techniques for Fiber to the Home (FTTH) in Africa, highlighting the continent's significant growth in internet usage alongside existing challenges. It evaluates various methods, including aerial and buried fiber installations, detailing their pros and cons, while emphasizing the importance of using existing infrastructure to minimize costs. The document also showcases innovative solutions, such as lightweight and efficient cables, that enhance deployment speed and reduce installation complexity.