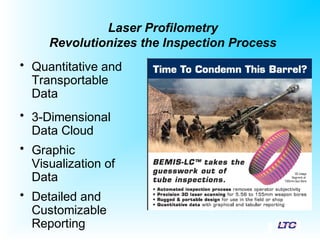

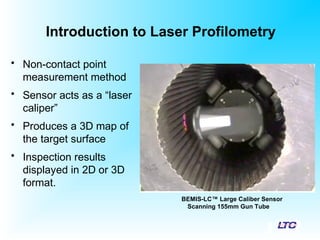

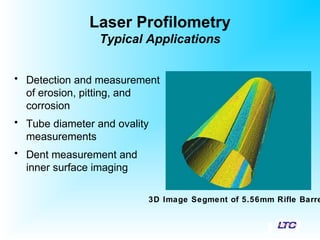

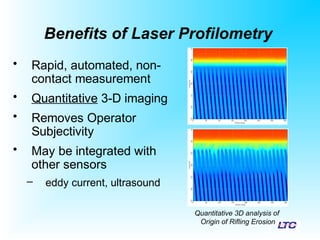

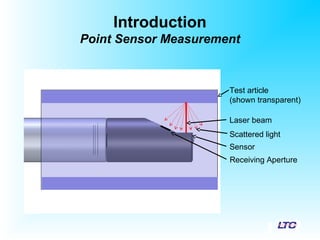

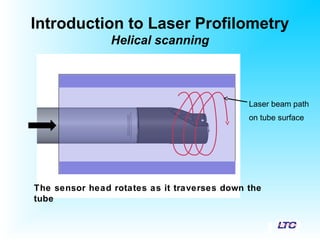

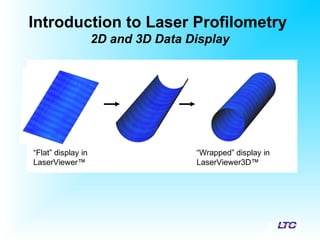

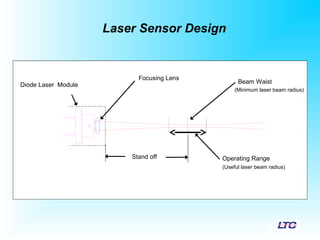

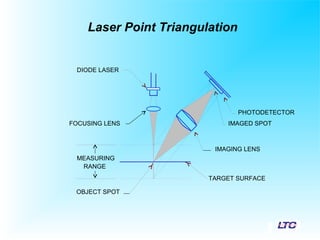

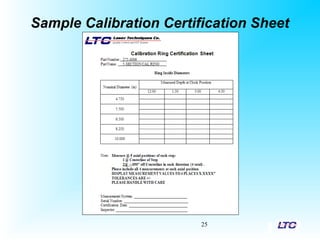

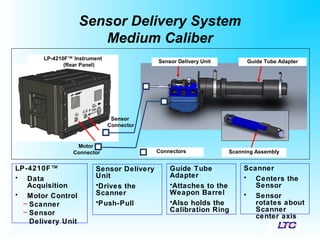

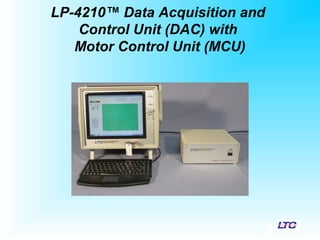

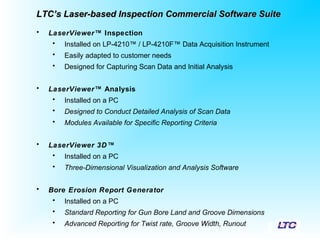

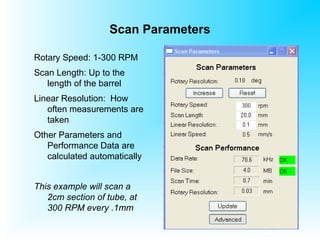

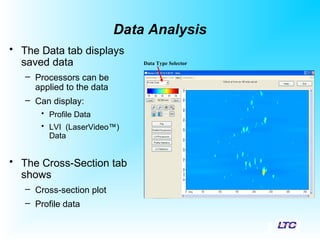

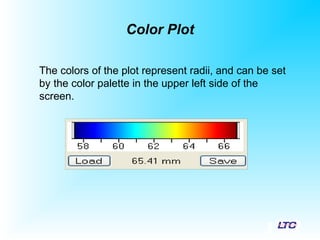

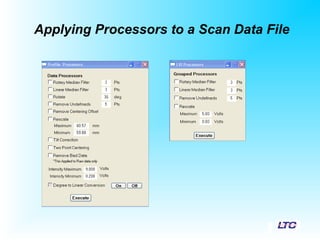

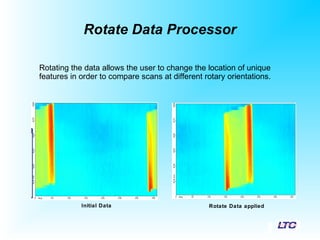

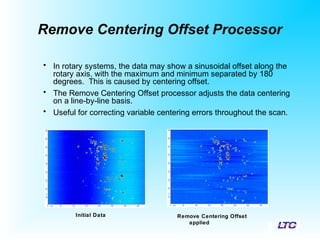

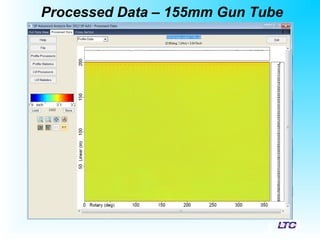

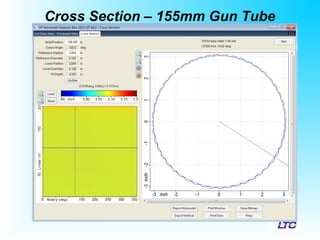

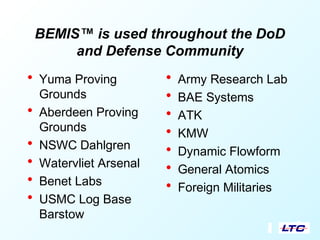

The document discusses the advancements in laser profilometry for inspecting gun tubes, detailing the technology's capabilities and applications for measuring bore erosion and detecting defects. It highlights the benefits of rapid, automated, and non-contact measurements, as well as the limitations such as the inability to detect subsurface features. Additionally, it outlines the components of the laser system and its integration into military and commercial applications to enhance safety and extend the operational life of critical equipment.