Logistics management aims to coordinate activities from procurement to delivery to satisfy customers at lowest cost. It involves planning material, part, and inventory movement and information flows. The ultimate goal is linking all levels of an organization to efficiently serve customers. Effective logistics and customer service can provide a competitive advantage by establishing cost leadership or value differentiation.

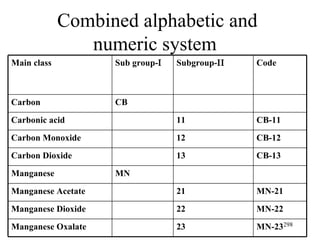

![• The Square Root Law states that the total

inventory in a future number of warehouses is

determined by multiplying the total inventory at

the existing warehouses by the square root of

number of future warehouses divided by

number of existing warehouses.

Mathematically, it is represented as under:

• L = [(L1) x {√ (W2÷ W1) }], where

• L= Total inventory in future warehouses

• L1= Total inventory in existing warehouses

• W1= Number of existing warehouses

250

• W2 = Number of future warehouses.](https://image.slidesharecdn.com/logistics-note-1-1230494545269880-2-120626083547-phpapp01/85/Logistics-notes-for-TYBMS-250-320.jpg)

![• For example, In a company there are 40

warehouses and the existing inventory is

2,00,000 units. If the number of warehouses

are reduced to 10 what will be impact on total

inventory.

• L1= 2,00,000

• W1= 40

• W2= 10

∴L= [(2,00,000) x {√ (10÷ 40 )}] = 1,00,000

• Thus, inventory will consist of 1,00,000 units

giving a reduction of 50%.

• Conversely, if the number of warehouses are

increased, the total inventory will increase.251](https://image.slidesharecdn.com/logistics-note-1-1230494545269880-2-120626083547-phpapp01/85/Logistics-notes-for-TYBMS-251-320.jpg)