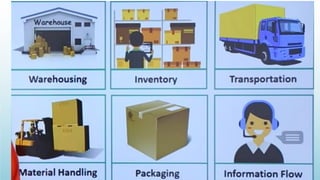

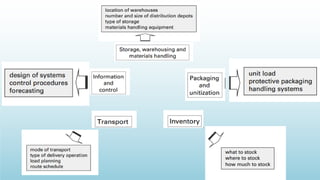

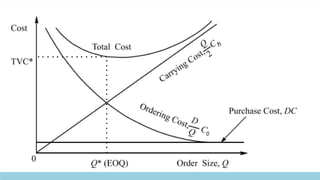

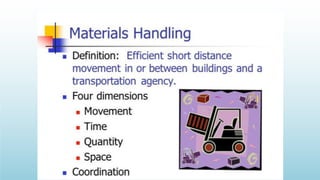

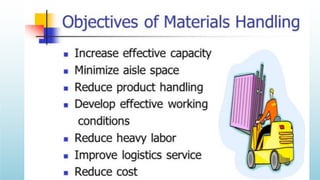

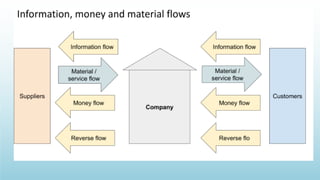

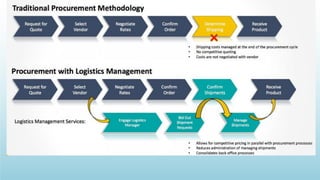

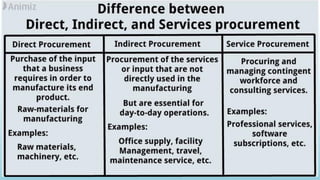

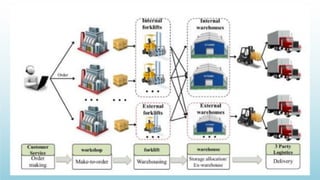

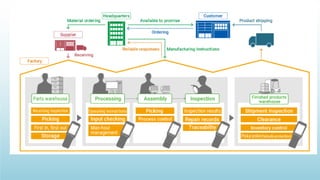

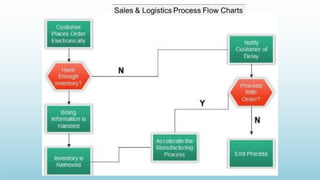

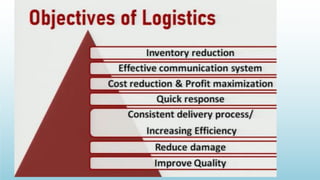

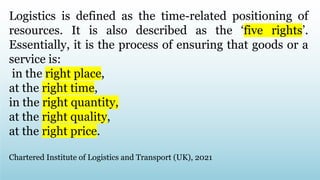

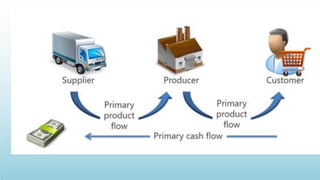

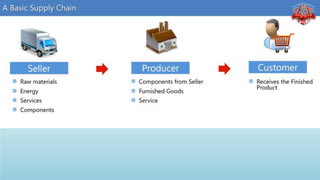

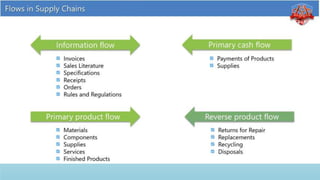

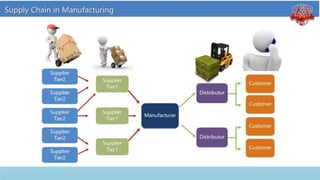

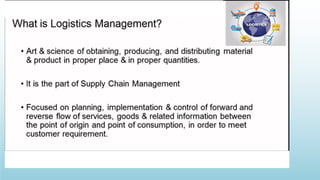

Logistics management is the planning, implementation, and control of efficient product flow from the point of origin to the point of consumption to meet customer requirements. It involves procurement, production, and sales logistics as well as reverse logistics. The key components of logistics include transportation, warehousing, inventory management, material handling, and information flow. Effective logistics is important for businesses as it allows getting the right products to the right customers at the right time and place.