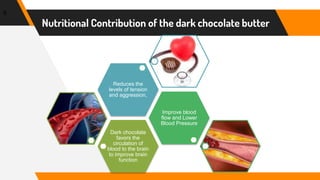

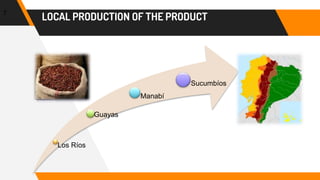

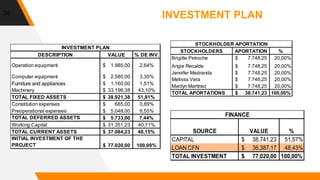

Chocolate Empire, a company founded by UC Santiago de Guayaquil students, specializes in producing and marketing 'Chocodarky,' a healthy dark chocolate butter made from organic cocoa. The product targets Ecuadorians aged 6-60, promoting health benefits such as improved circulation and brain function. With plans for local and international expansion, the company aims to innovate in the chocolate sector while competing with established brands.