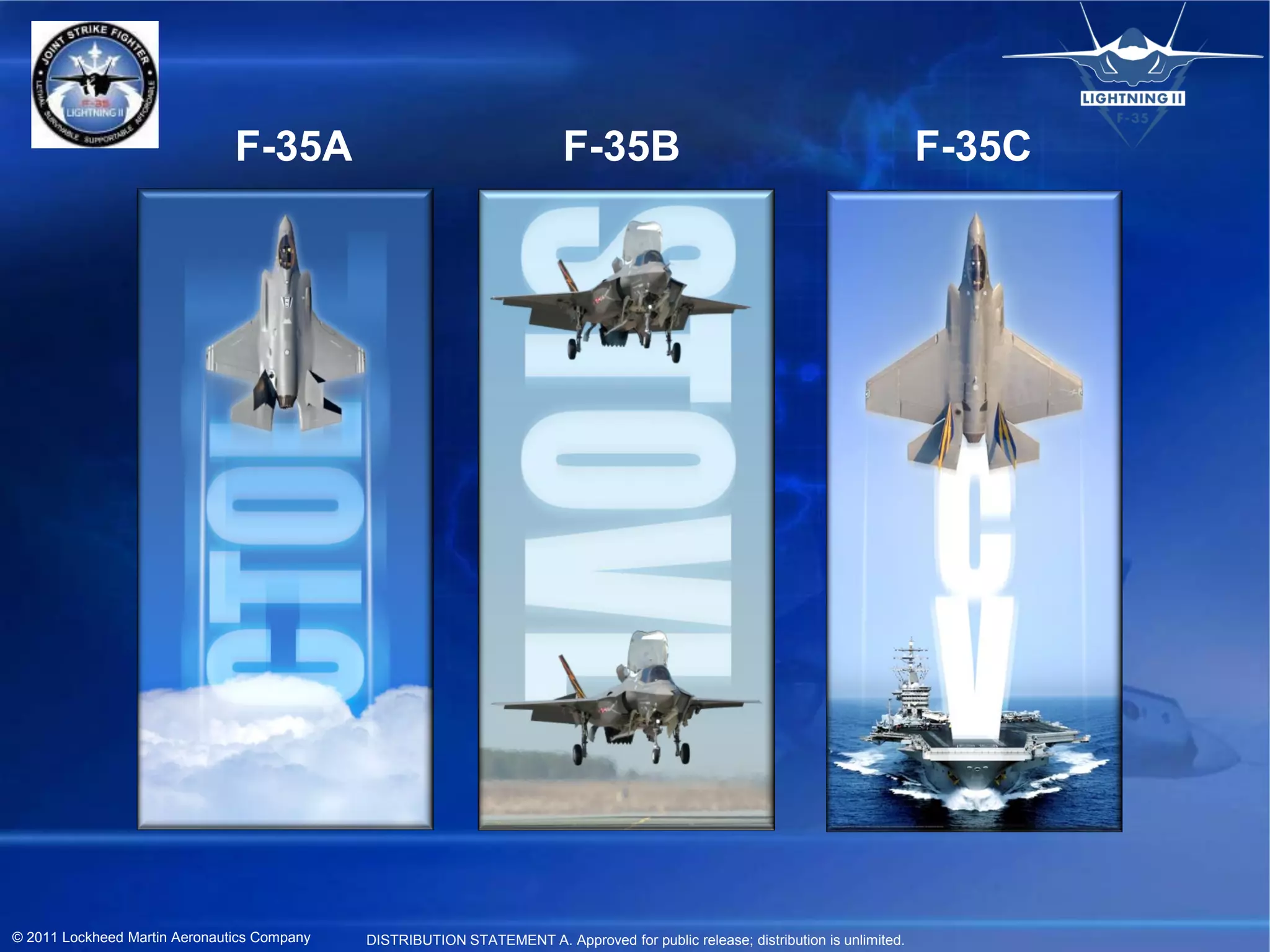

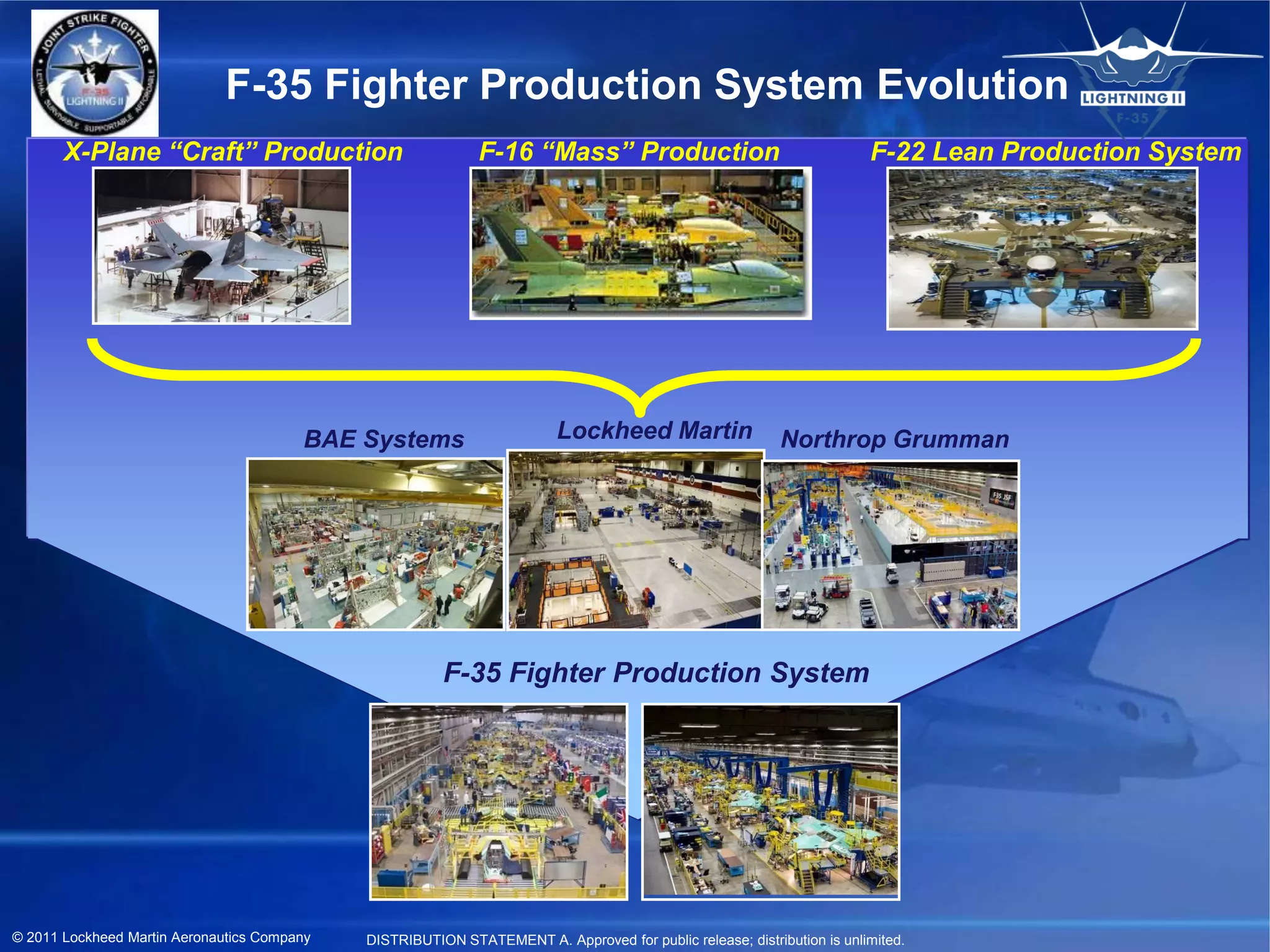

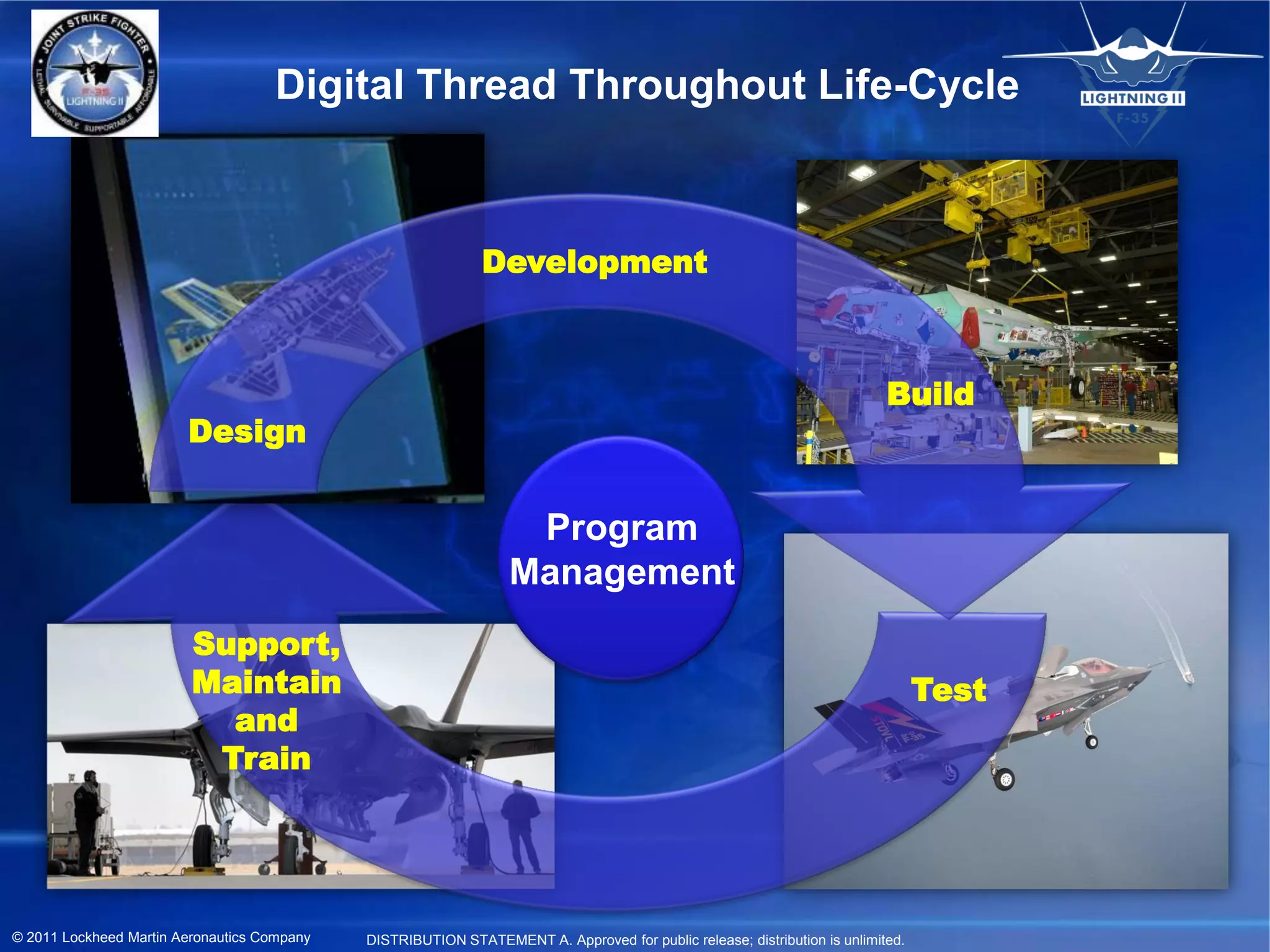

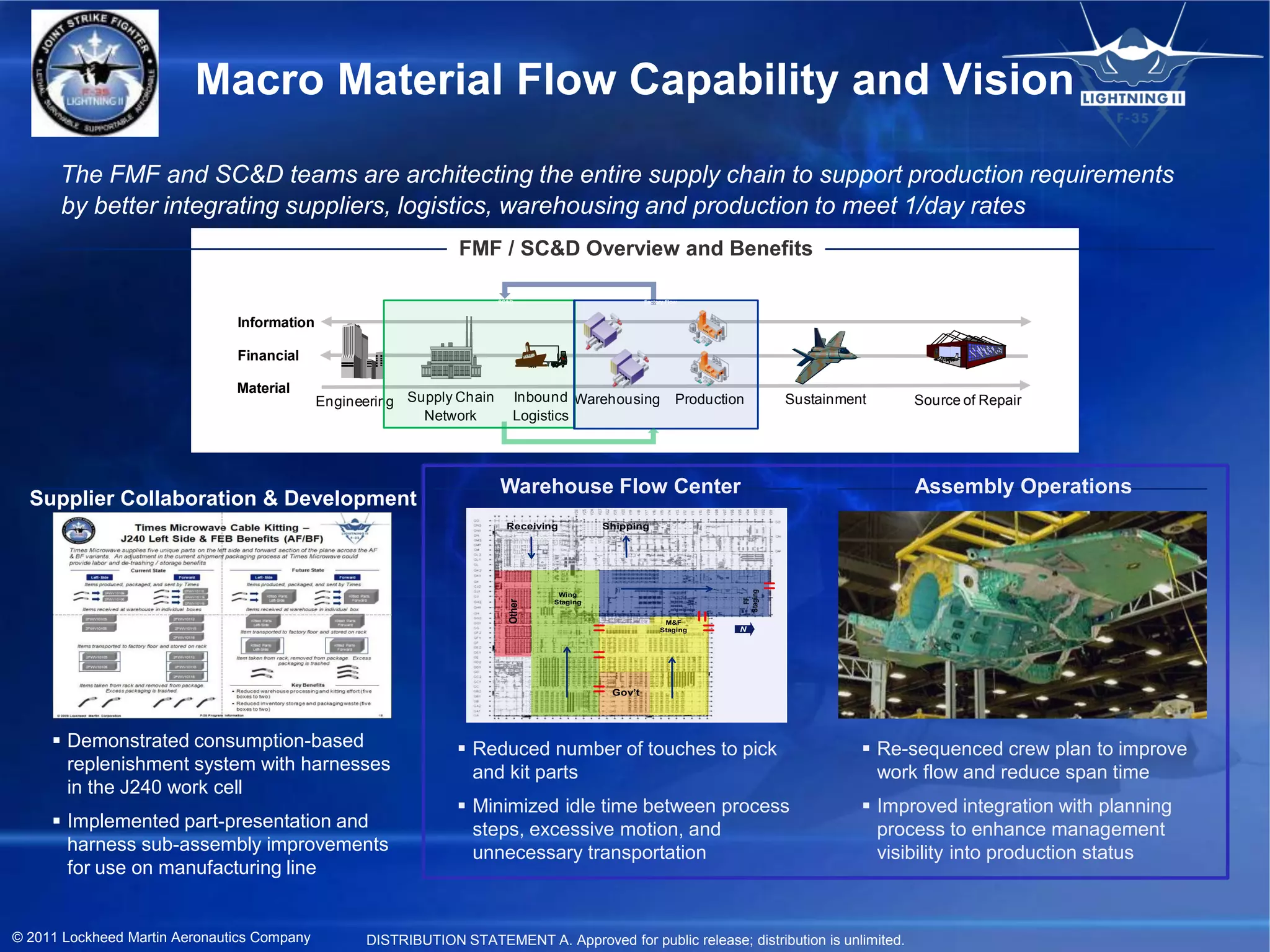

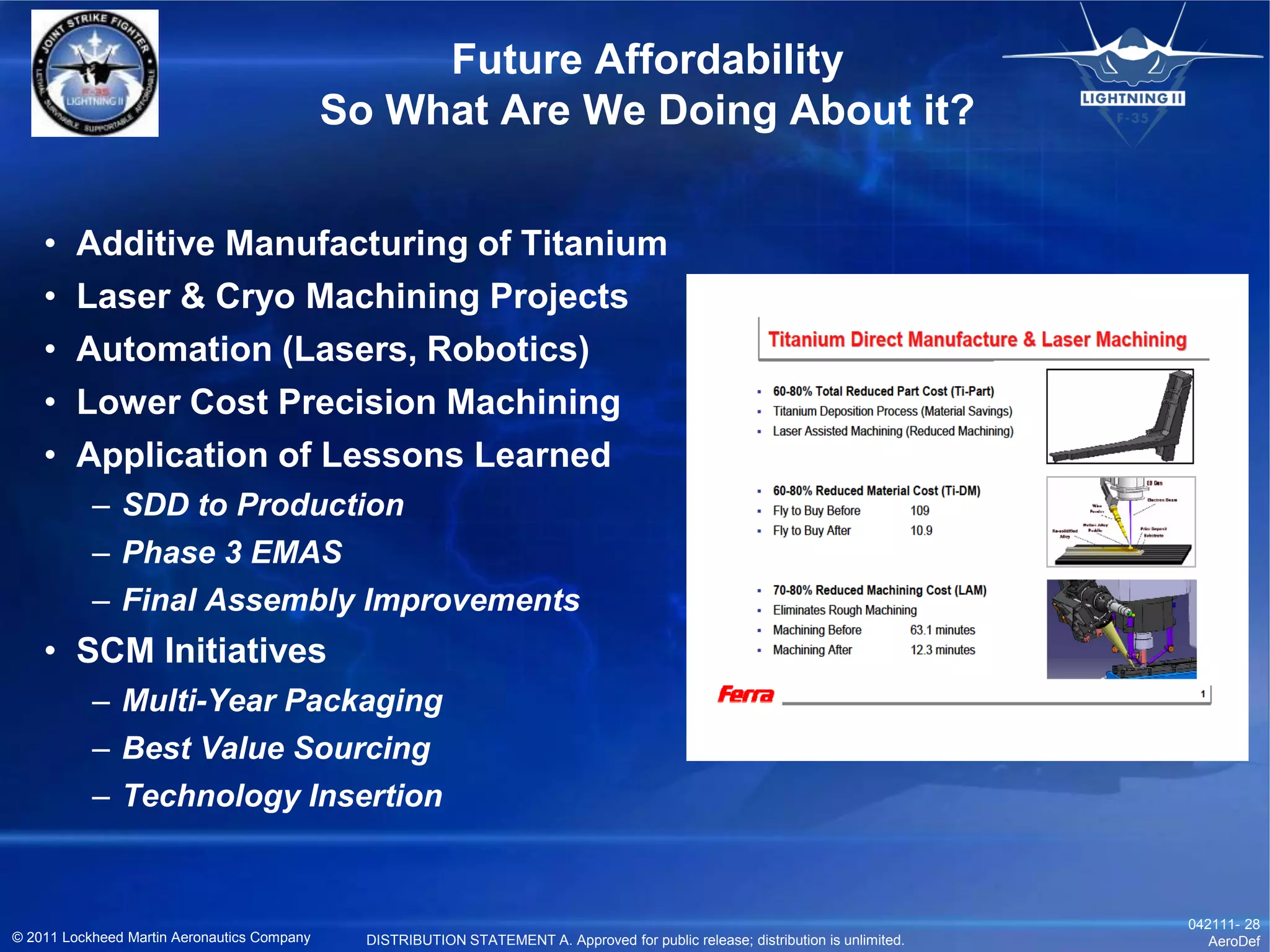

This document discusses Lockheed Martin's focus on affordability for the F-35 Lightning II fighter jet program. It summarizes the three main variants of the F-35—the F-35A conventional takeoff and landing variant, the F-35B short takeoff and vertical landing variant, and the F-35C carrier-based catapult takeoff variant. It also outlines Lockheed Martin's goals of achieving economies of scale through design commonality across variants, implementing new lean manufacturing processes to reduce costs over time, and engaging international partners in the production process.