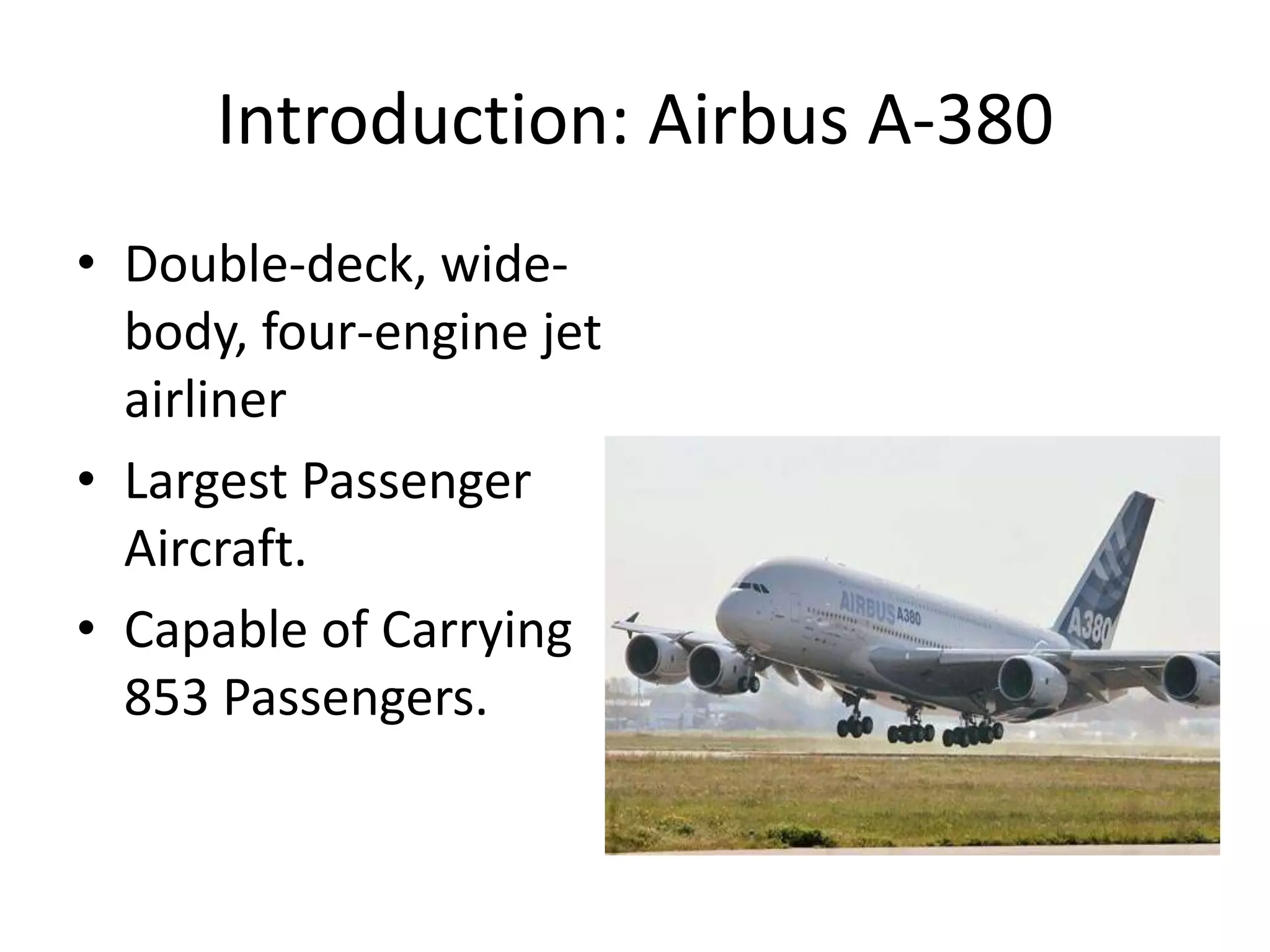

The Airbus A-380 was developed to gain strategic advantage over Boeing, enter the very large aircraft segment, and change the industry structure from point-to-point to hub-and-spoke. Airbus organized design teams and conducted extensive market analysis to develop a double-deck design capable of carrying over 800 passengers. The A-380 underwent various tests and received safety approvals before production in facilities across Europe and with components from global suppliers. While orders have been placed, the A-380 program aims to fill gaps and change the commercial aviation industry.