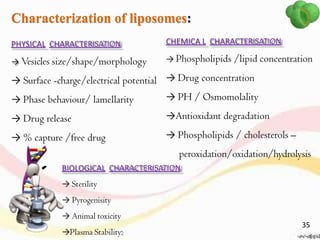

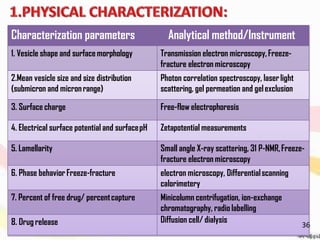

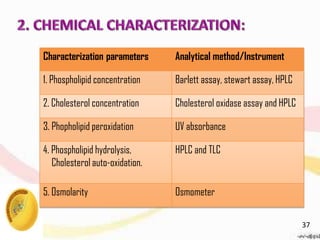

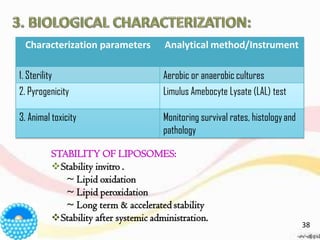

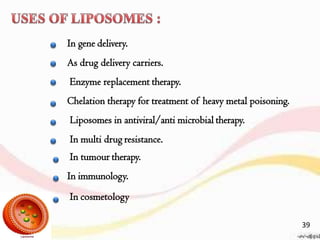

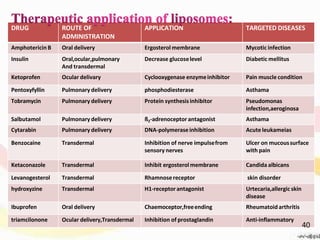

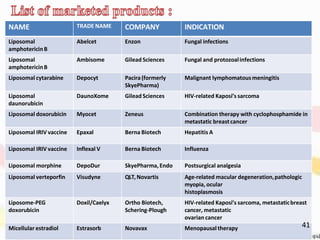

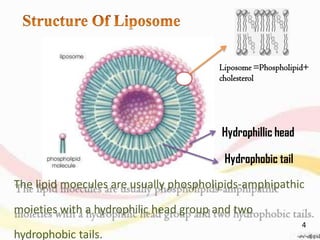

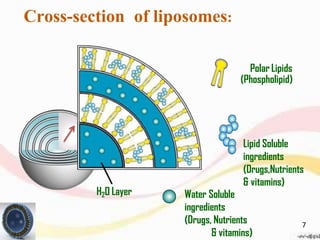

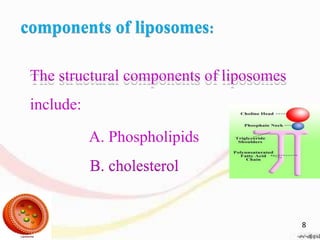

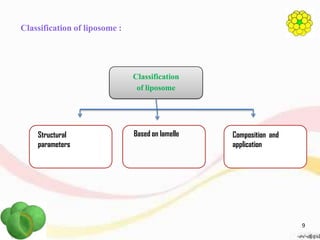

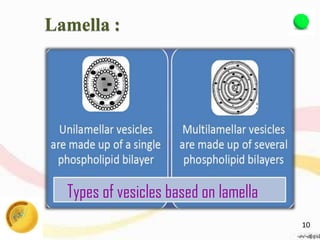

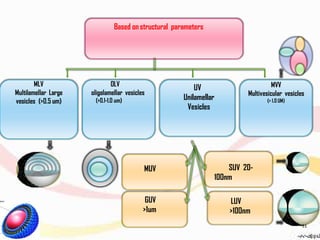

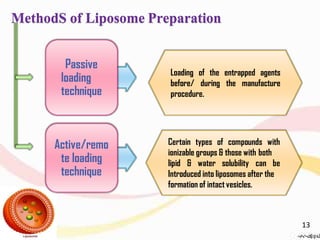

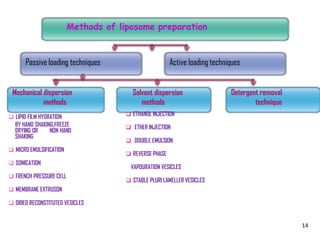

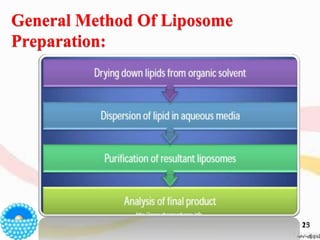

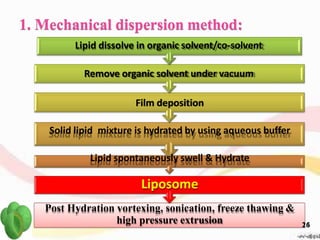

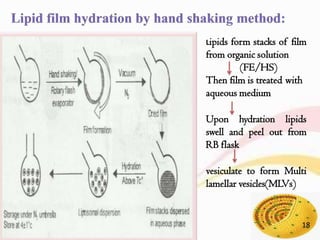

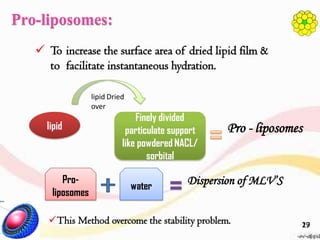

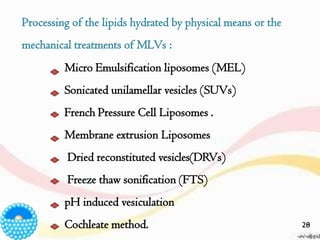

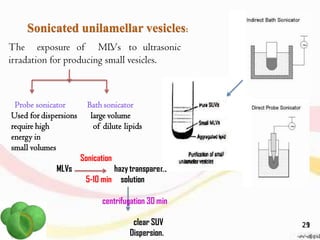

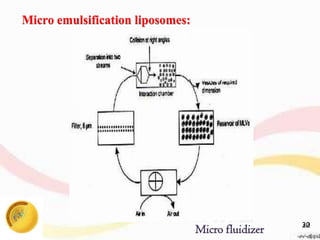

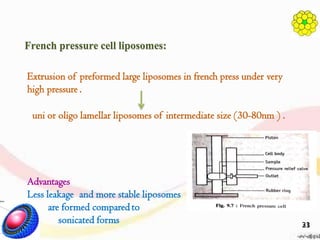

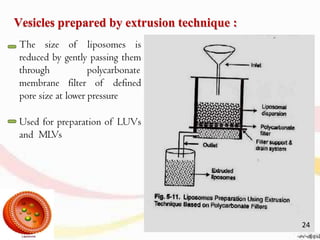

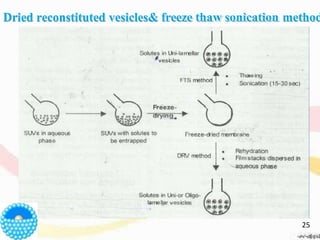

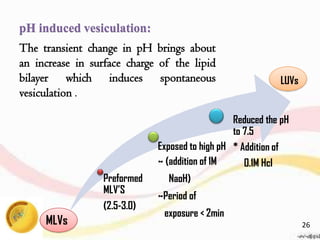

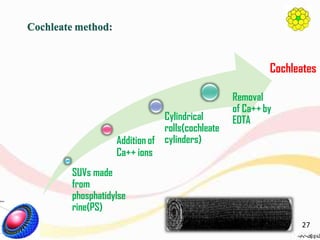

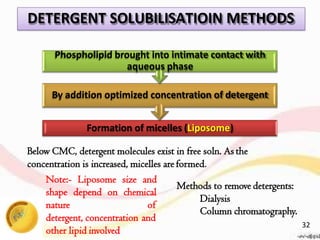

This document provides an overview of liposomes, including their structure, advantages, disadvantages, components, preparation methods, characterization, and applications. Liposomes are spherical vesicles composed of phospholipid bilayers that can encapsulate aqueous volume. They were first produced in 1961 and range in size from 20 nm to several micrometers. Liposomes provide benefits like selective targeting to tissues, increased efficacy, reduced toxicity, and improved pharmacokinetics. Common preparation techniques include lipid film hydration, microemulsification, sonication, and detergent removal. Liposomes are characterized based on their physical properties and are used to deliver drugs for diseases like cancer, fungal infections, and more.

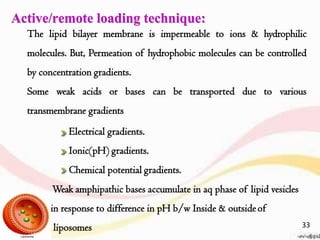

![pH gradient is created by preparingliposomes

with low internal pH.

Addtn of base to extraliposomal medium.

[Basic compds ( lipophilic (non ionic) athigh

pH & hydrophilic(ionic) at lowpH)]

Lipophilic (UNPROTONATED) drug diffuse through

thebilayer

At low pH side, the moleculesare

predominantly protonated .

Exchange of external medium by gelextrusion

chromatorapghy with neutralsolution.

Weak bases like doxorubicine,

adriamycin and vincristine are

encapsulated.

Solute bearing no

charge at neutral pH

Liposomes with low

internal pH

Neutral solute passes

easily through bilayer

membrane by diffusion

Charge aquired by solute

inside liposomes makes

them unable to exit

34](https://image.slidesharecdn.com/liposomes-converted-200409090918/85/Liposomes-converted-34-320.jpg)