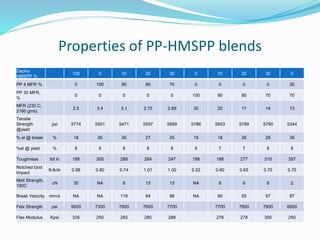

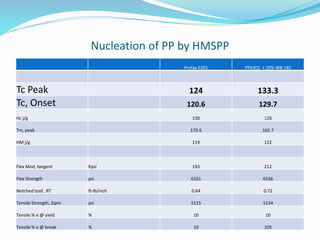

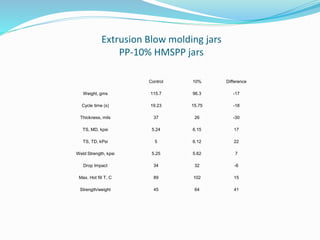

This document provides an overview of high melt strength polypropylene (HMS PP), including:

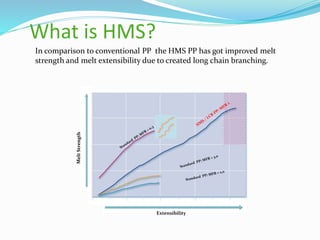

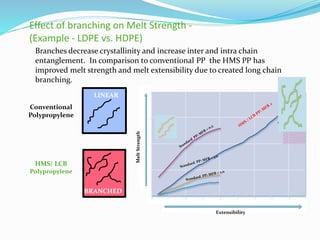

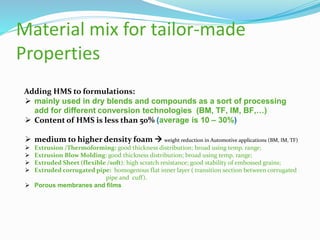

- HMS PP has improved melt strength and extensibility compared to conventional PP due to long chain branching. This increases entanglement and reduces crystallinity.

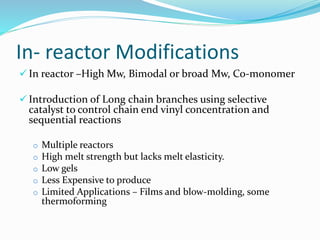

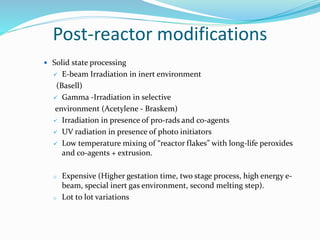

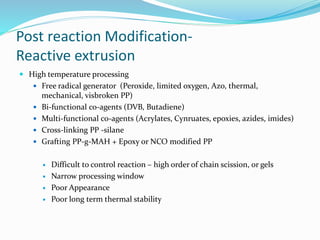

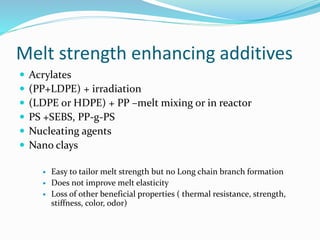

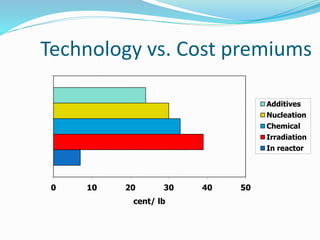

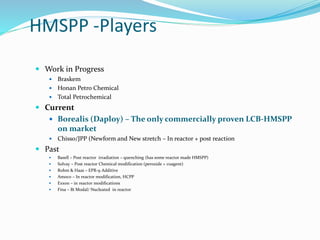

- HMS PP can be produced through in-reactor or post-reactor modifications. In-reactor is cheaper but offers limited applications, while post-reactor offers more control but is more expensive.

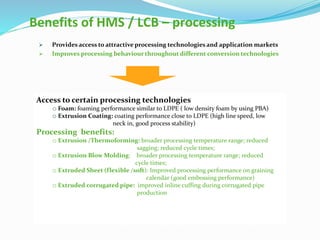

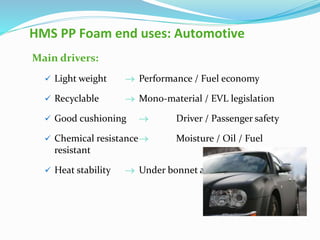

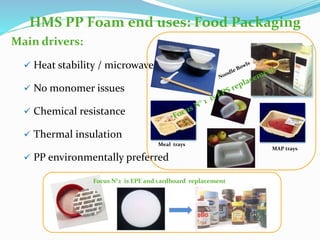

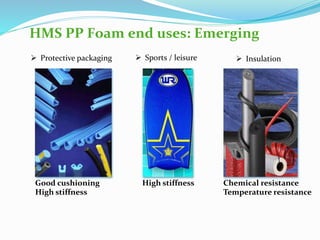

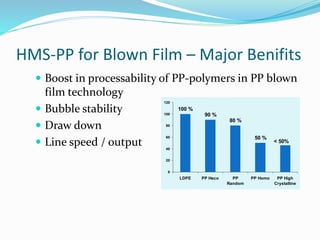

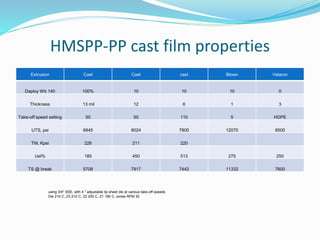

- Key applications of HMS PP include foams, blow molded containers, films, coatings, and fibers due to benefits like improved processing, higher output rates, and downgauging potential. The automotive and food packaging industries are major end users.

![HMS as modifier

0

5

10

15

20

25

0 100 200 300

Meltstrength[cN]

Extensibility [mm/s]

Standard iPP

MFR 0.3 g/10'

HMS

MFR 3 g/10'

LDPE

MFR 3 g/10'

85

120

0

20

40

60

80

100

120

140

PP-Homo; MFR 3 Daploy™ HMS-Homo * addition

Output[kg/h]

Processing aid increased output, less neck in

Nucleating agent mechanics downgaging potential

Extensibility downgaging potential](https://image.slidesharecdn.com/ab3ac8a5-a90c-4d09-ba25-0ae1a39f5d4b-160816202759/85/LINKEDINHMSPP-25-320.jpg)