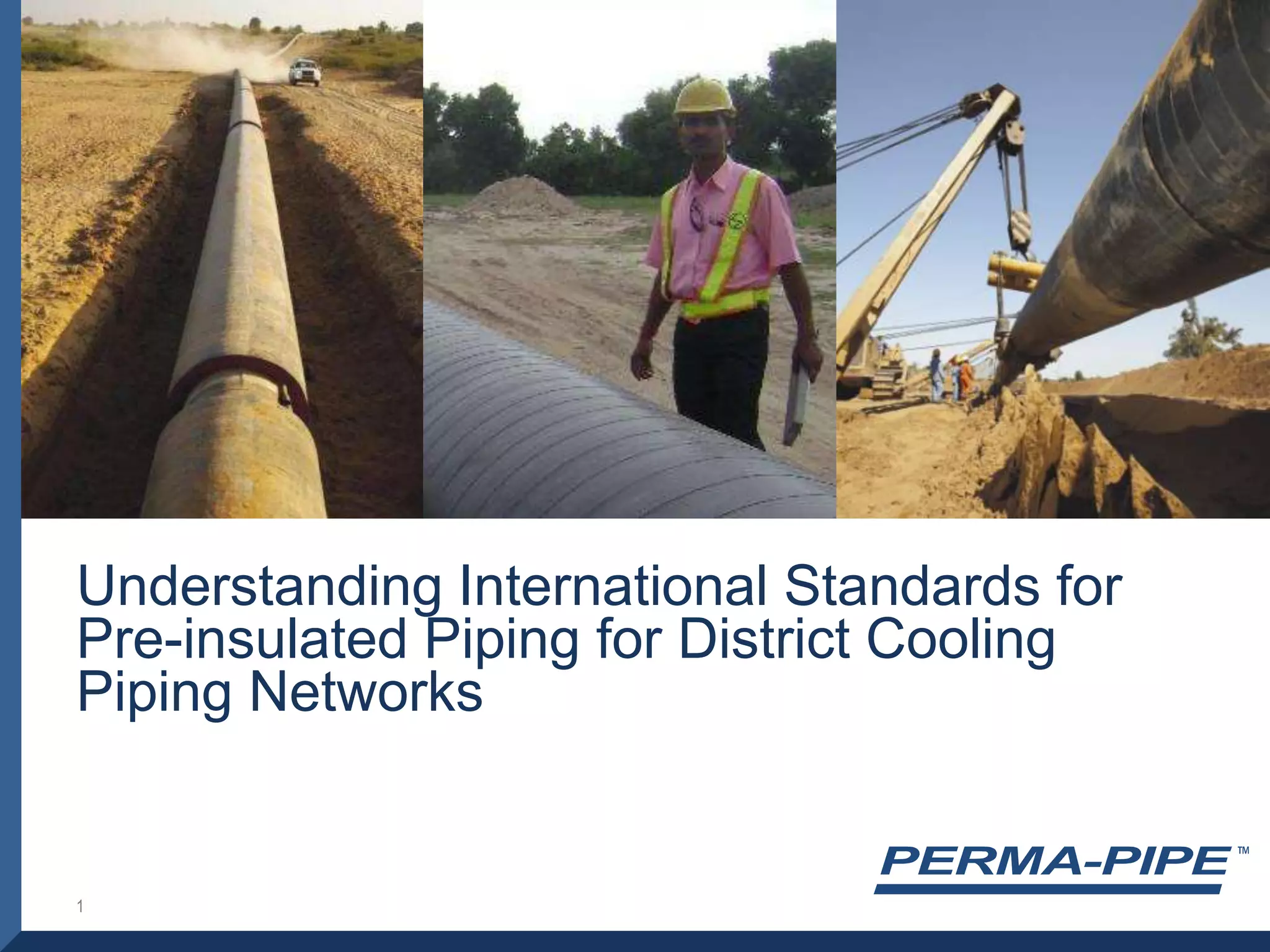

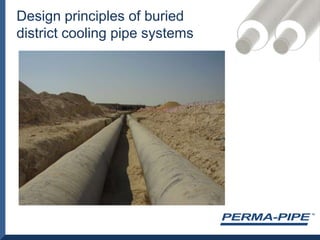

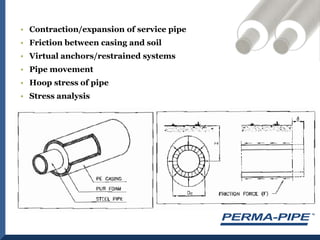

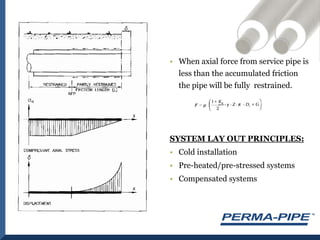

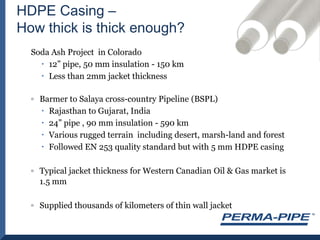

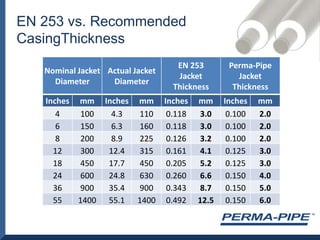

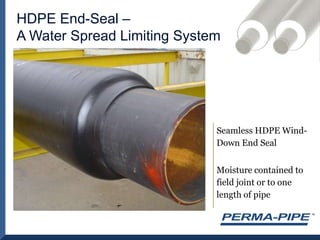

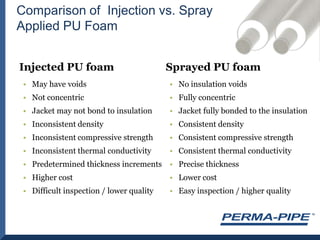

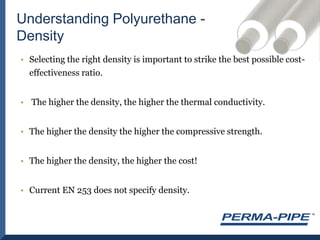

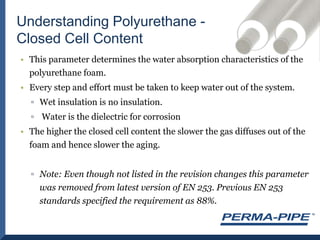

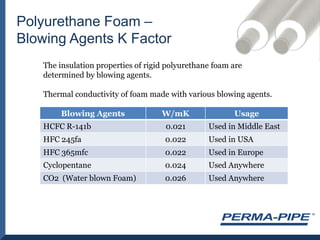

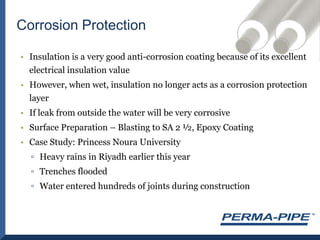

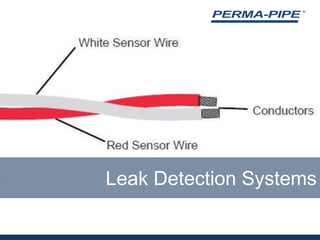

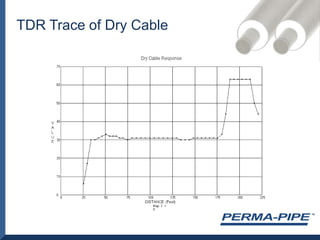

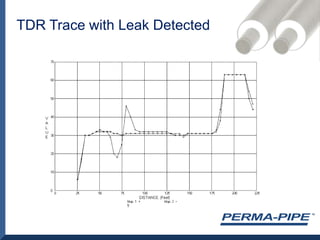

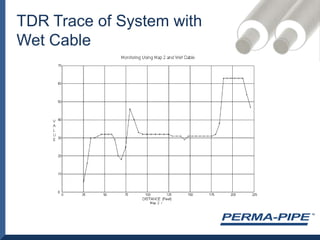

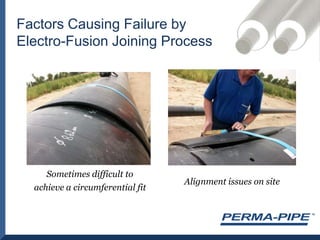

The document discusses international standards for pre-insulated piping systems used in district cooling networks. It provides an overview of Perma-Pipe, the largest supplier of pre-insulated piping systems in North America and the Middle East. It then discusses key components of pre-insulated piping systems including the HDPE casing, polyurethane foam insulation, corrosion protection, leak detection, and field joint sealing methods.