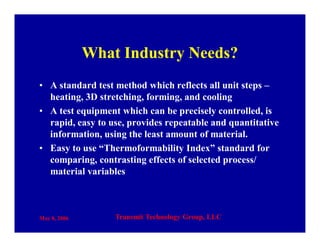

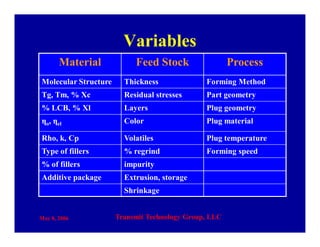

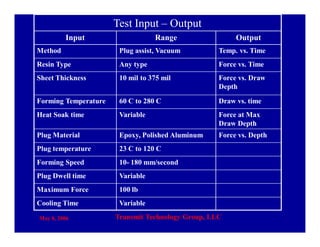

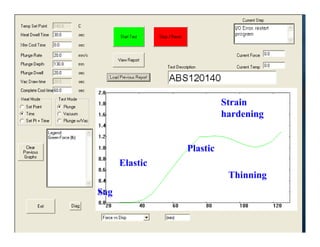

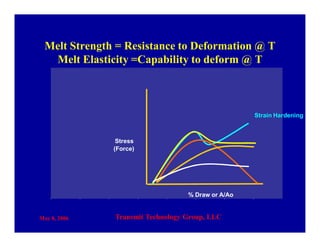

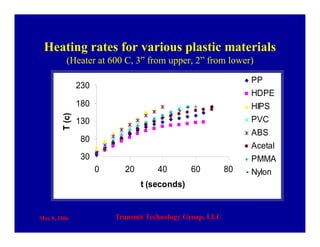

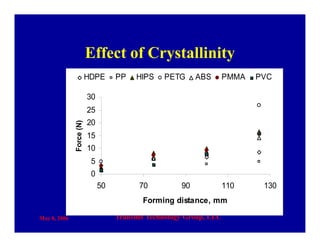

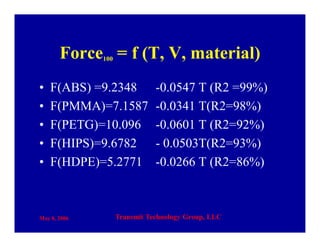

This document discusses applications of a thermoformability analyzer to test and analyze plastic materials. It begins by outlining the need for a standardized quantitative test method for measuring thermoformability. It then describes the structure-property relationships that impact thermoformability and limitations of current test methods. The document outlines the thermoformability analyzer, which aims to address current limitations through a test that reflects the full thermoforming process. It presents various results the analyzer can provide on factors that influence thermoformability and how these results can help processors. Finally, it proposes a thermoforming index to standardize comparing materials' thermoformability.

![May 8, 2006 Transmit Technology Group, LLC

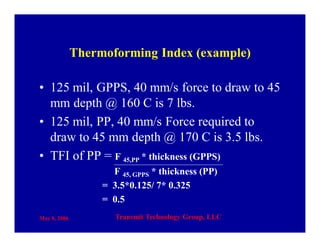

How to Standardize?

• Thermoforming Index (TFI)

– Force required to draw a sheet of thickness X at

speed Y mm/second using a Plug of specified

geometry G at Temperature Tf to area ratio A

(or volume ratio V), with plug temperature Tp.

• TFI = [Force (M, Tm)/ Force (GPPS, Ts)]](https://image.slidesharecdn.com/dbc81352-4d8a-4b57-b0ef-a7104ac8c2f0-160816202412/85/SPE-Aug15-43-320.jpg)