Embed presentation

Downloaded 15 times

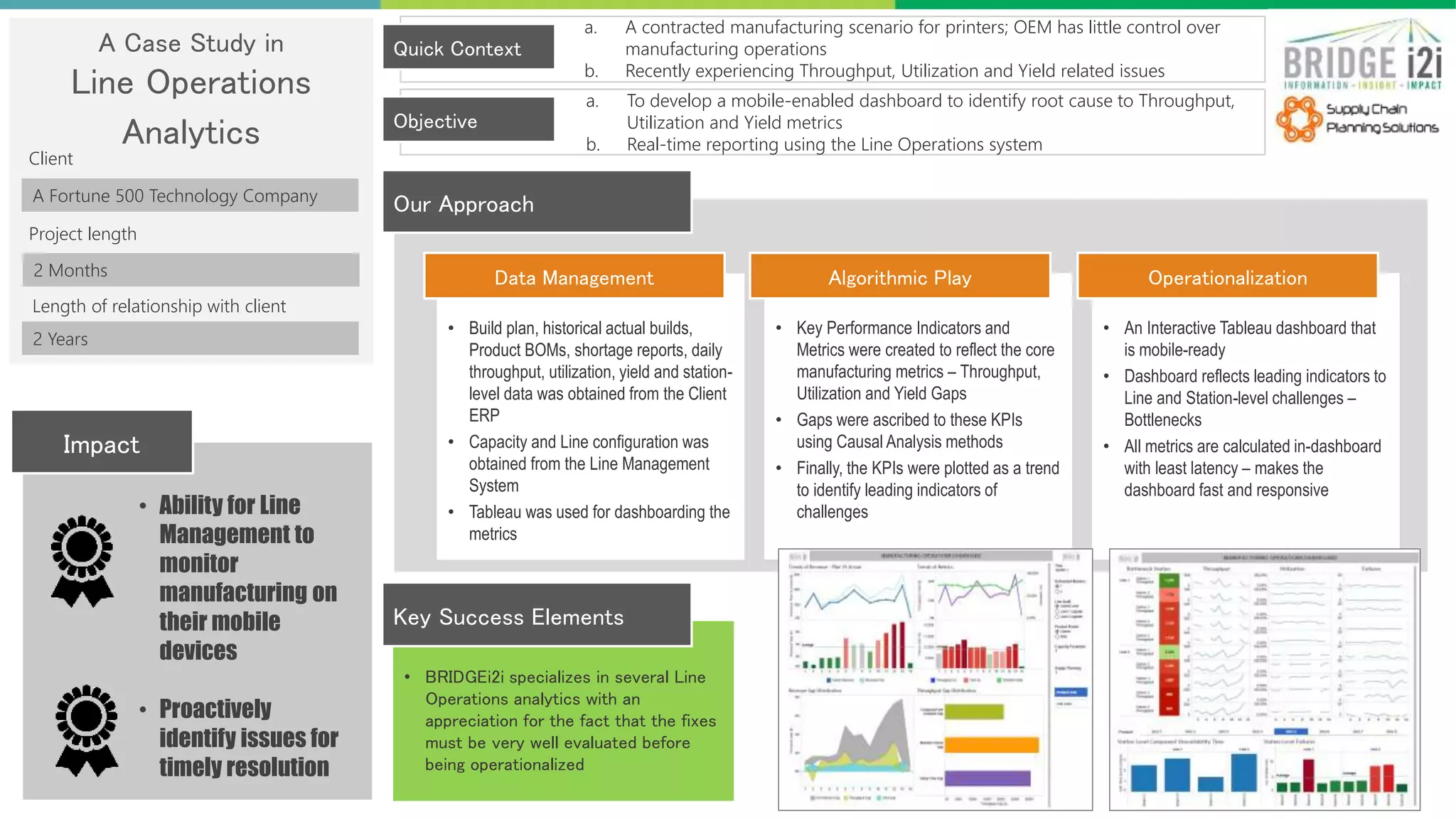

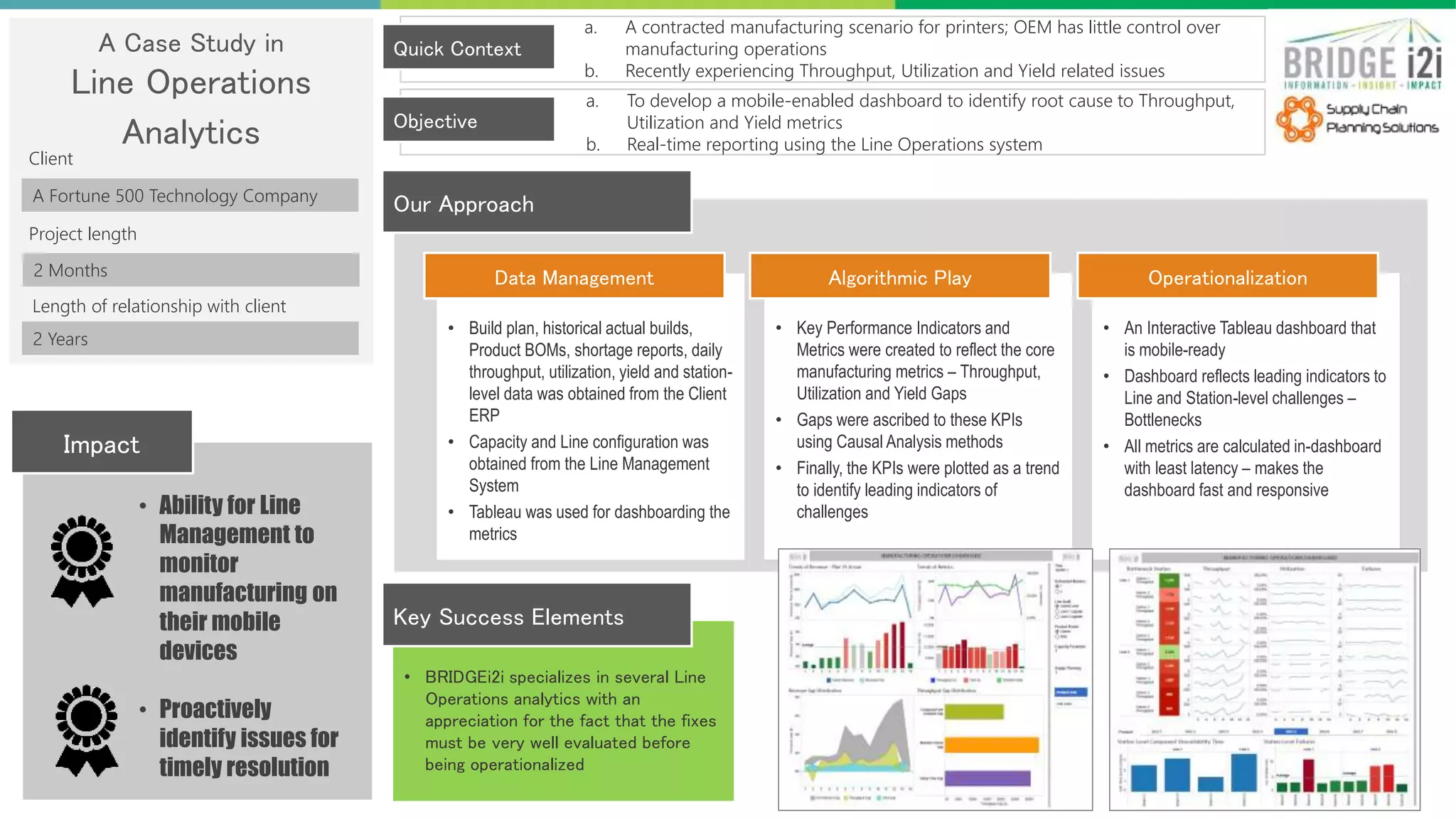

A technology company was experiencing issues with throughput, utilization, and yield in its printer manufacturing operations. BRIDGEi2i worked with the company over 2 months to develop an interactive Tableau dashboard accessible on mobile devices. The dashboard calculated key performance metrics from historical build data, product bills of materials, shortage reports, and other operational data sources. Using causal analysis methods, the dashboard identified gaps in throughput, utilization, and yield metrics and plotted trends to reveal leading indicators of line and station-level bottlenecks. This allowed line management to proactively monitor manufacturing performance and address issues in real-time for timely resolution.