Embed presentation

Downloaded 29 times

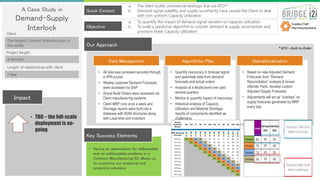

The document presents a case study on a contract manufacturer's challenges with demand-supply interlock while building commercial desktops that are built-to-order. It highlights the client's efforts to address demand signal volatility and supply uncertainty through data analysis and predictive algorithms to improve capacity utilization. Key elements include secure data access, demand forecasts, and adjustments to supply forecasts based on reconciled demand analysis.