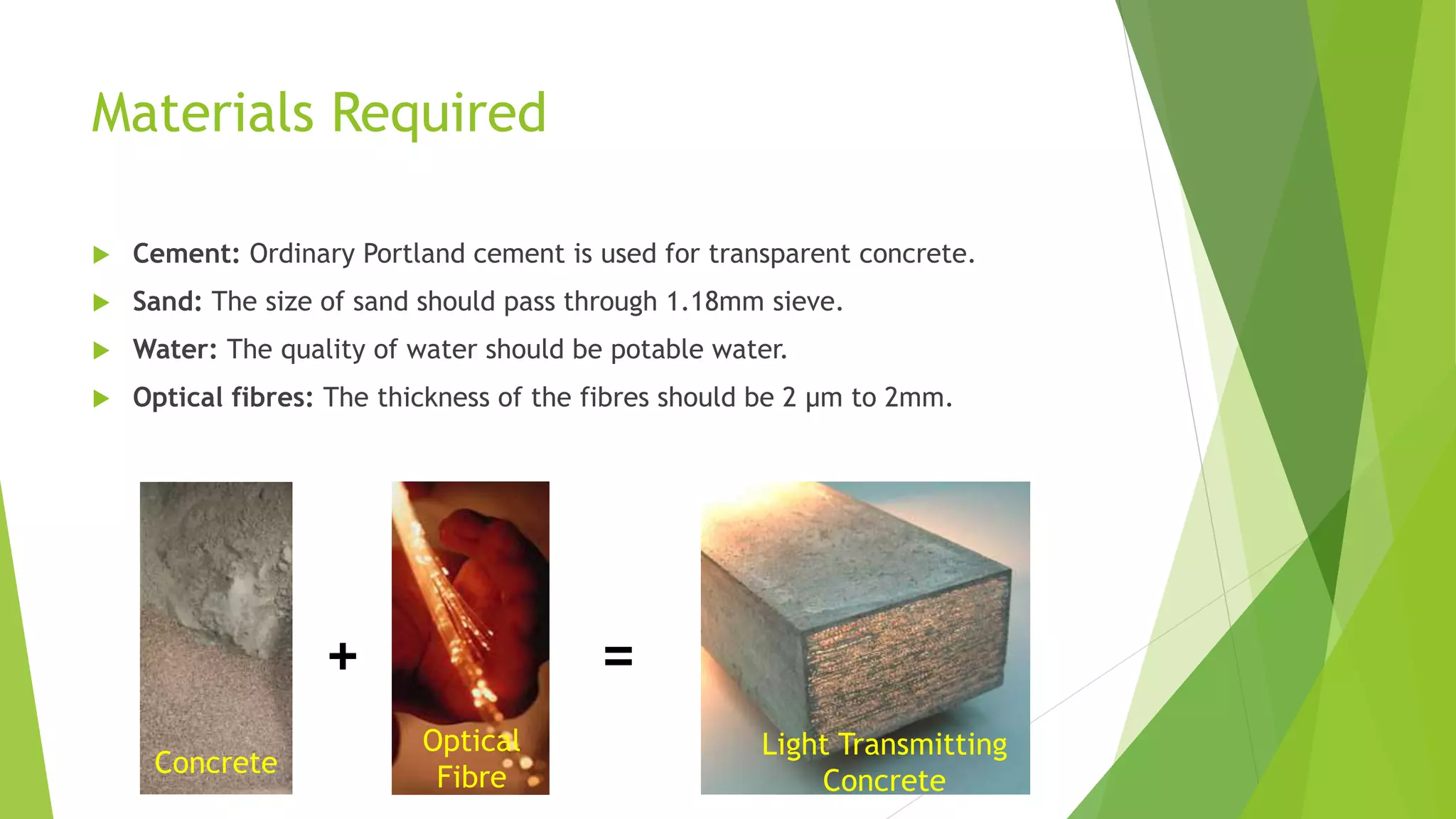

This document summarizes the key aspects of translucent concrete, also known as light transmitting concrete or LitraCon. It was first developed in 2003 by Hungarian architect Aron Losonzi. The concrete becomes translucent through the uniform distribution of thin optical fibers throughout the material. As light passes through the fibers, it is transmitted across the concrete through the process of total internal reflection. The manufacturing process involves casting thousands of parallel optical fibers directly into the concrete mixture. This allows light to pass through the material while maintaining its compressive strength. Some applications of translucent concrete include illuminated sidewalks, building walls, and stairwells.