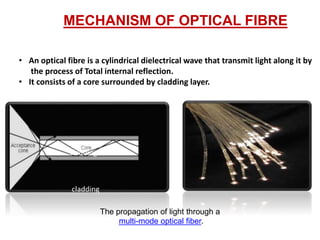

This document summarizes a study on transparent concrete called LiTraCon. LiTraCon is produced by embedding parallel optical fibers in a concrete mixture, which allows light to transmit through the concrete. The document outlines the materials used, fiber types, construction process of concrete blocks using plastic optical fibers, mechanical properties that are similar to conventional concrete, applications like partitions and floors, and advantages like aesthetic properties and energy savings. It concludes that transparent concrete is a novel architectural material that maintains strength while providing lighting and aesthetic benefits.