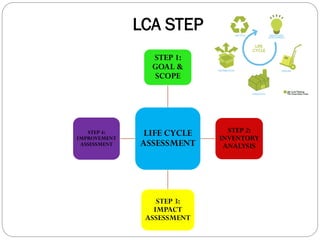

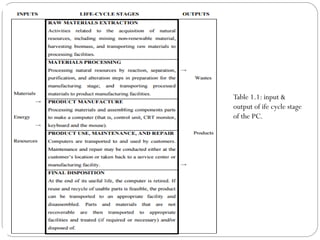

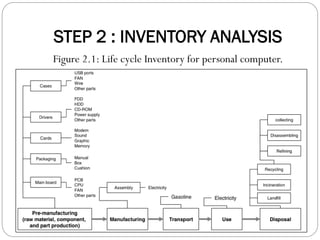

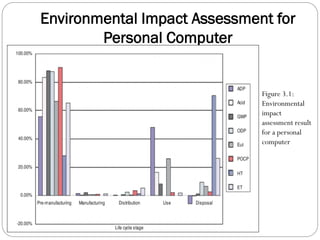

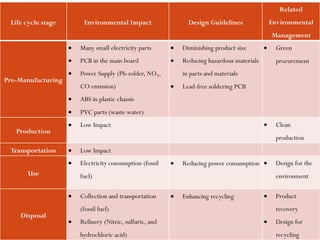

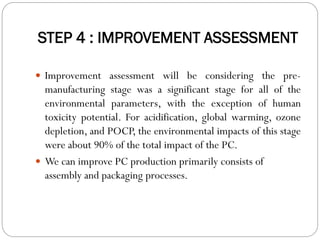

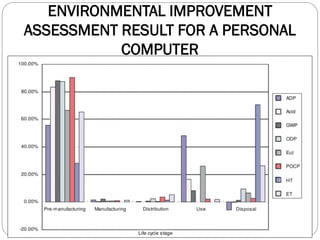

1) This document summarizes the results of a life cycle assessment (LCA) conducted on a personal computer. The LCA followed the four steps of goal and scope definition, inventory analysis, impact assessment, and improvement assessment.

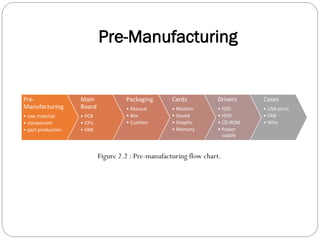

2) The pre-manufacturing stage, which involves production of components and parts, was found to be the largest contributor to most environmental impact categories.

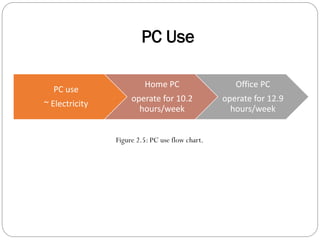

3) The use stage, particularly for office computers used over 12 hours per week, also significantly contributed to environmental impacts due to energy consumption.

4) The LCA results can be used to identify priority areas for improving the design of PCs and their components to reduce environmental impacts over the product lifecycle.