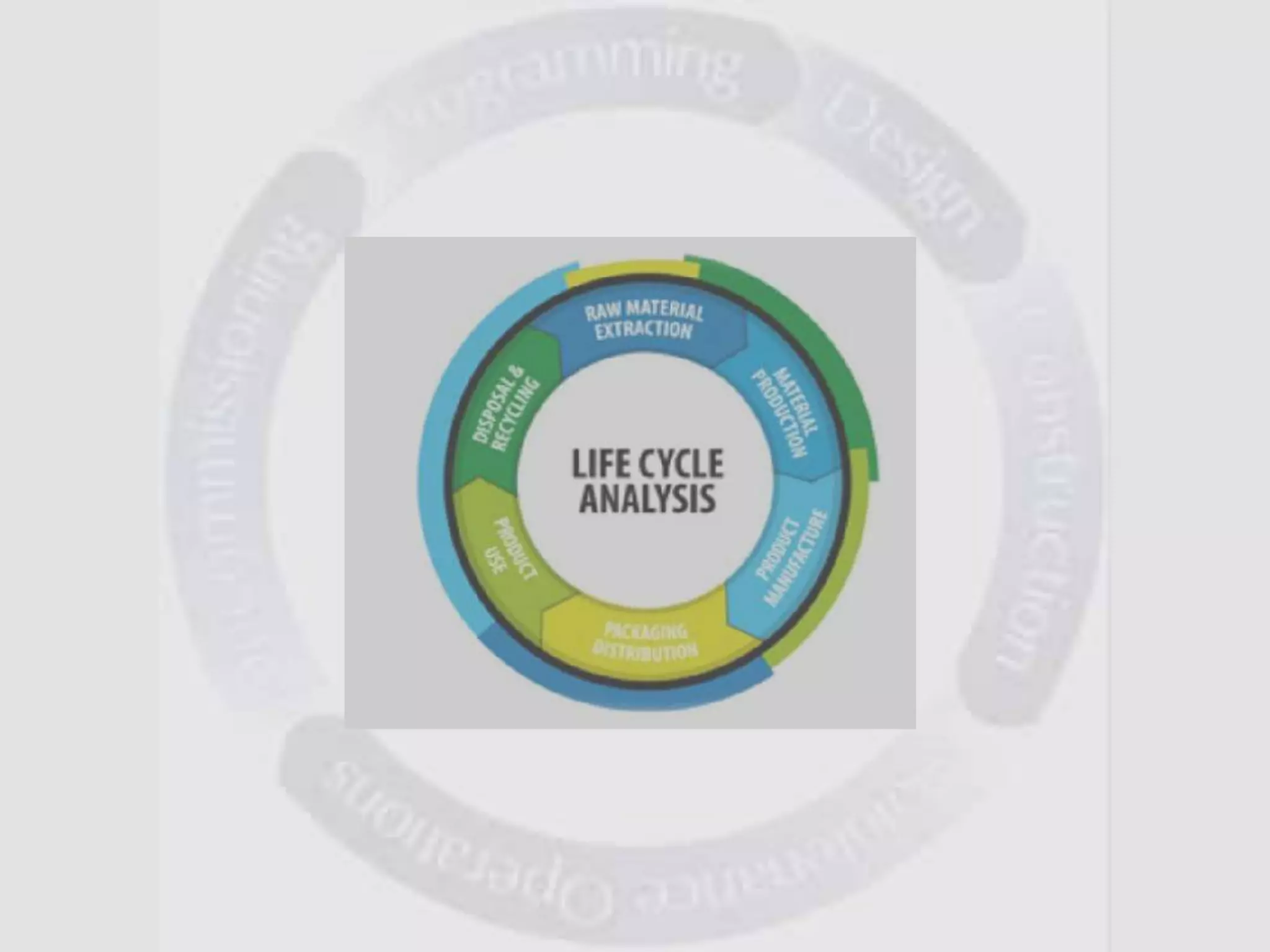

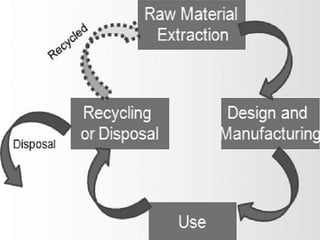

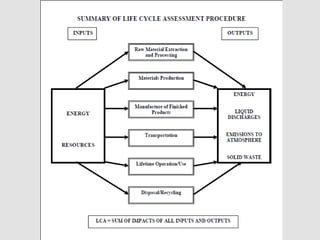

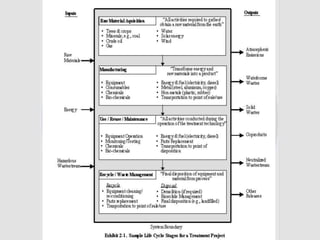

Life Cycle Assessment (LCA) is a tool used to evaluate the environmental impacts of a product or process throughout its lifecycle, from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. An LCA involves compiling an inventory of all energy and material inputs and environmental releases, evaluating the potential environmental impacts associated with identified inputs and releases, and interpreting the results to help improve product design and inform decisions.