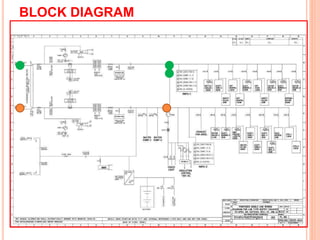

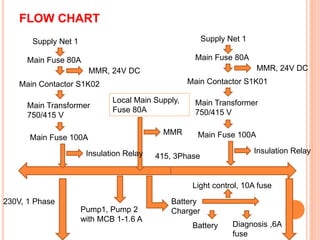

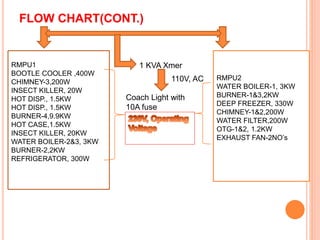

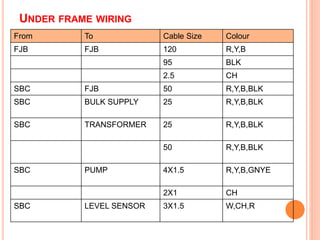

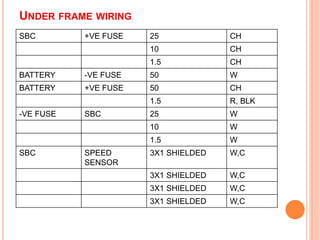

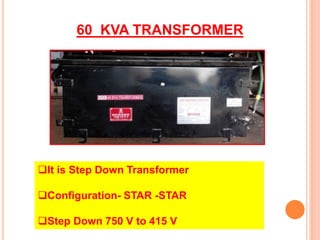

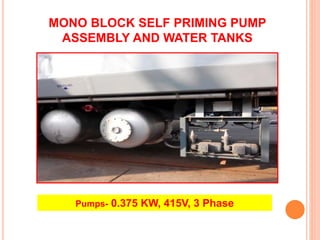

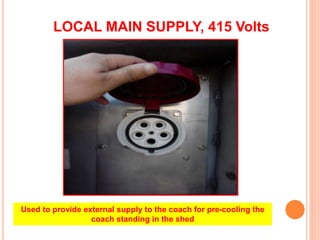

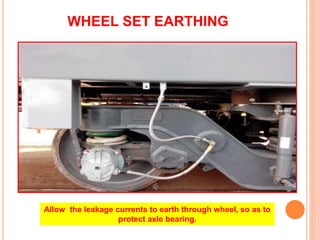

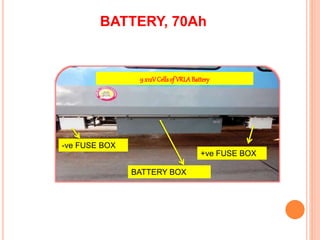

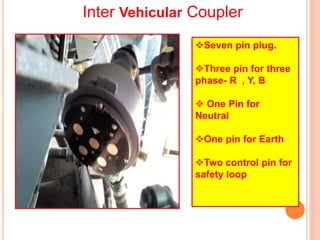

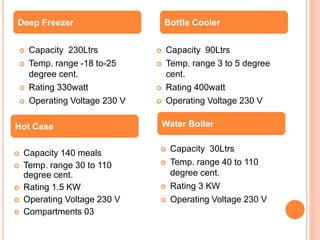

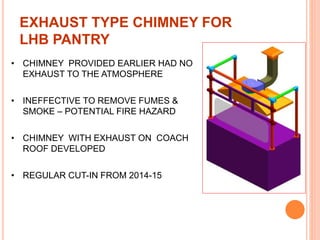

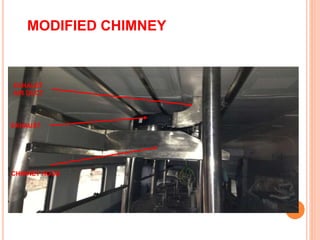

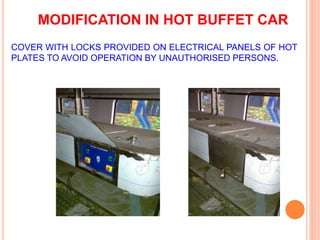

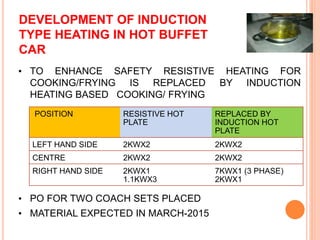

This document discusses the LHB hot buffet coach used in Indian Railways. It provides an overview of the types of LHB coaches including air-conditioned and non-air conditioned options. It also describes the key electrical systems on the coach like the transformer, wiring, batteries, and switchboard cabinet. Furthermore, it outlines the equipment in the pantry area such as the hot plates, water boiler, refrigerator and discusses new developments like installing exhaust chimneys and replacing resistive hot plates with induction plates.