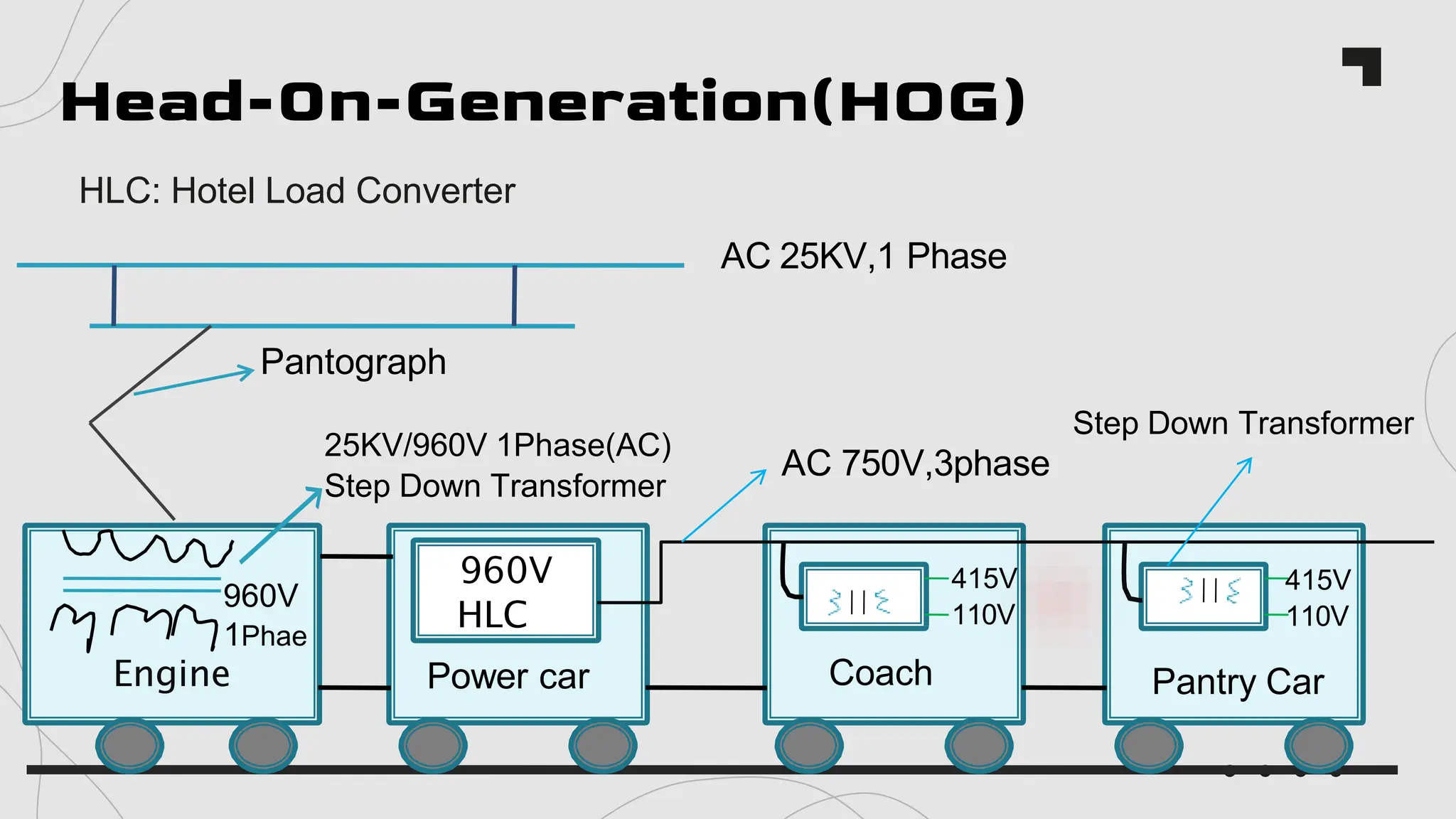

This presentation compares lighting systems for Indian Railways coaches and trains. It discusses the two main types of coaches, ICF and LHB, and describes the features of LHB coaches including their longer length, lighter weight, higher speeds, and improved passenger comfort. It then covers the different train lighting systems including self-generation, end-on-generation, mid-on-generation, and head-on-generation. Head-on-generation is identified as the most efficient and cost-effective system, providing power from the locomotive at the front of the train. The presentation concludes by comparing the costs per unit of electricity for different lighting systems, with head-on-generation being the most affordable option.