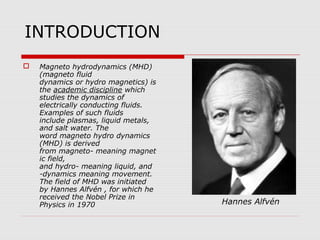

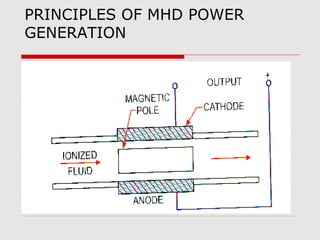

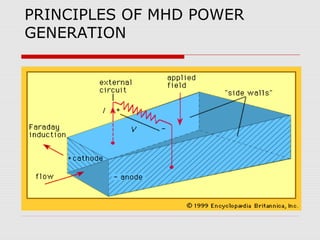

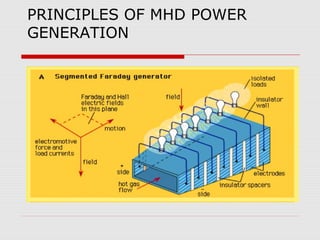

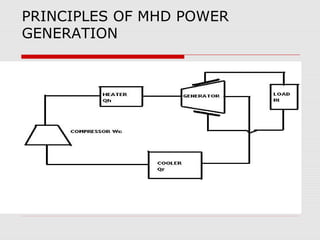

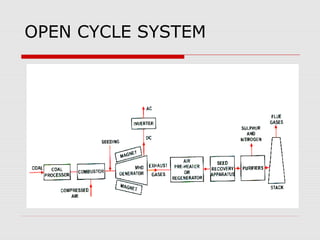

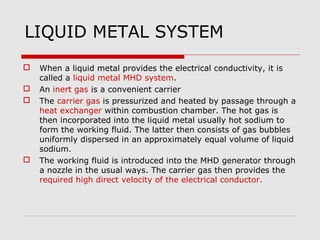

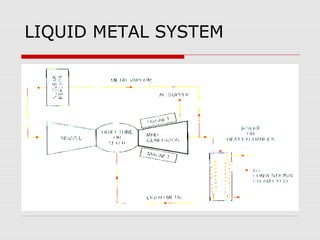

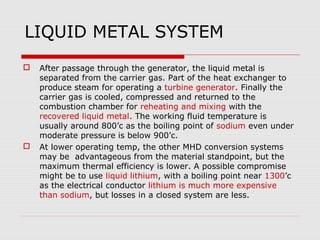

This document provides an overview of magneto hydro dynamic (MHD) power generation. It discusses the principles of MHD generation where an electrically conducting fluid is passed through a magnetic field to generate electricity. It describes two main types of MHD systems - open cycle systems which use combustion gases as the working fluid, and closed cycle systems which either use a seeded inert gas or liquid metal as the working fluid to maintain conductivity in a closed loop. The document explains the basic components and working of MHD generators and their advantages over conventional power plants.