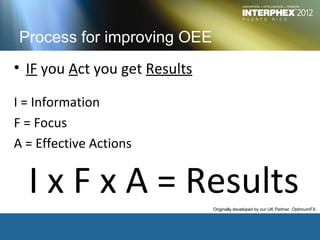

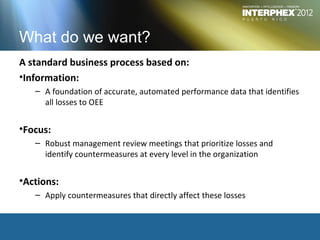

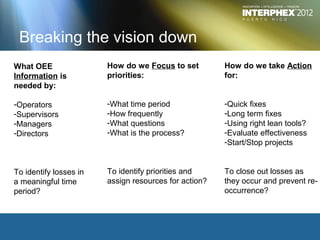

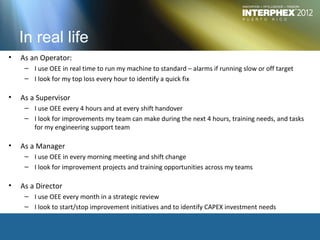

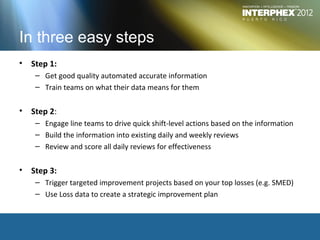

The document discusses the use of Overall Equipment Effectiveness (OEE) to enhance production by identifying and reducing losses related to availability, performance, and quality. It emphasizes the importance of accurate data, focused management processes, and actionable countermeasures to drive sustainable improvement. The proposed approach includes training teams on data interpretation, engaging them in quick actions, and initiating targeted improvement projects based on identified losses.