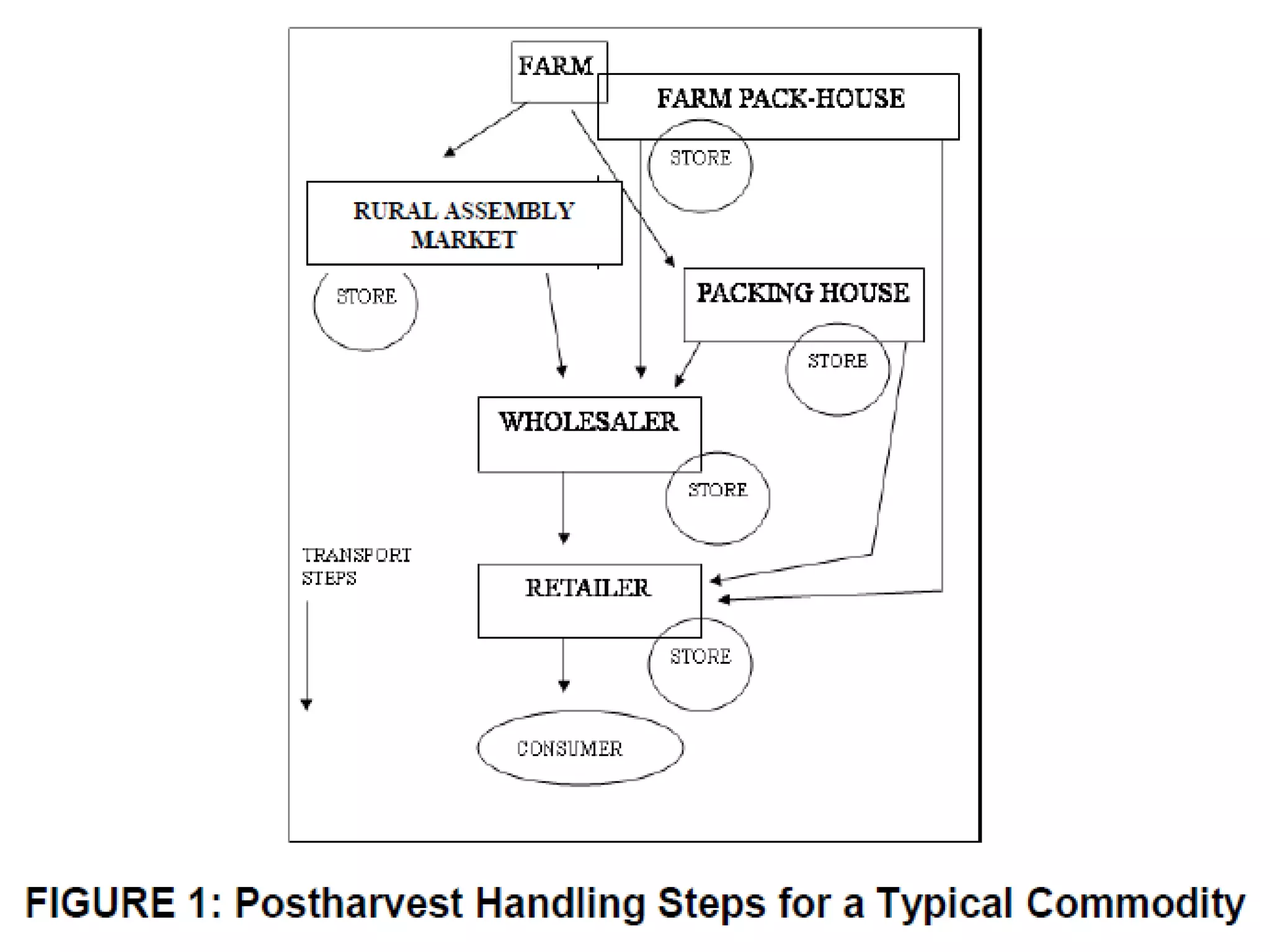

The document discusses postharvest technology, including:

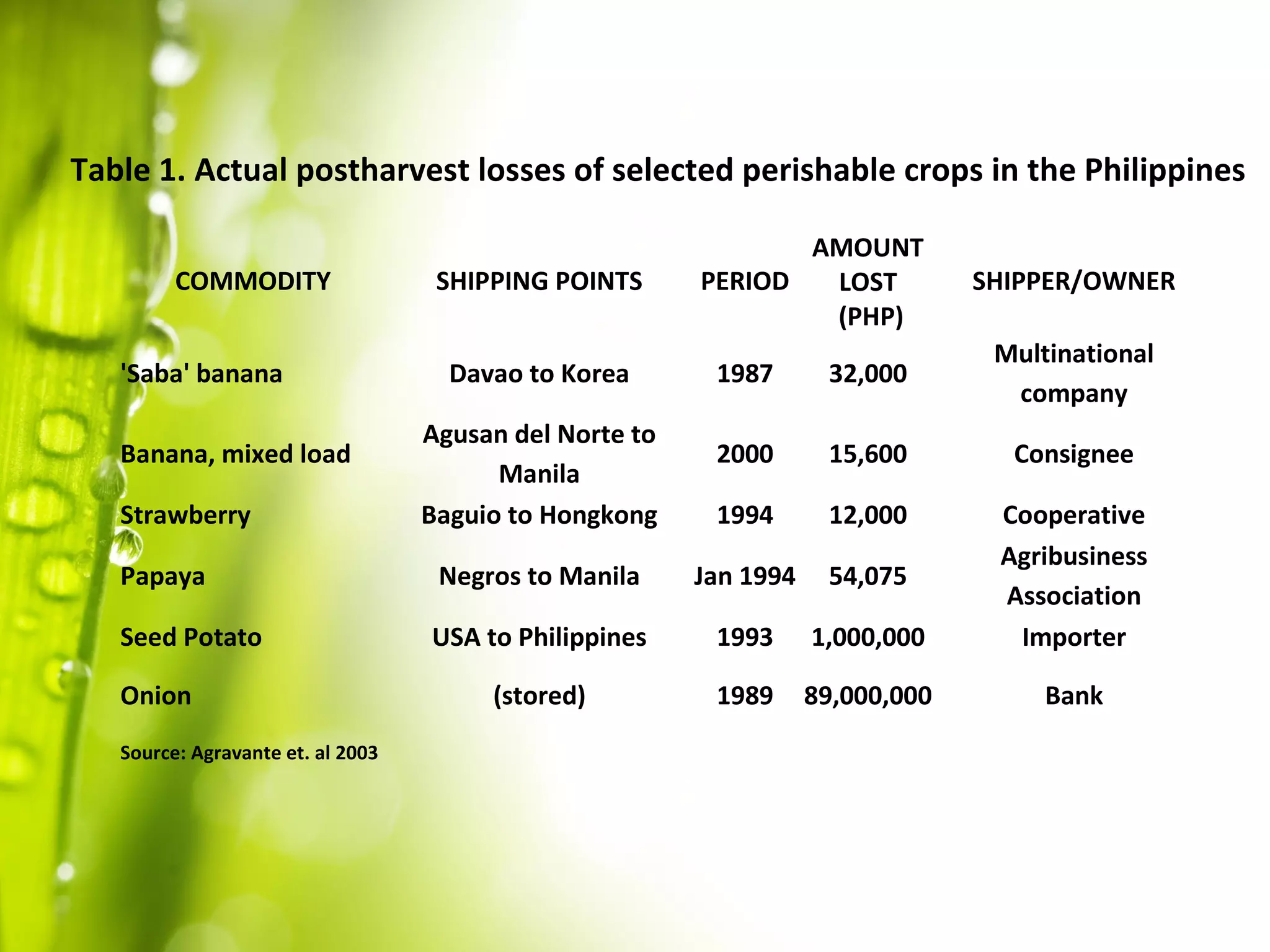

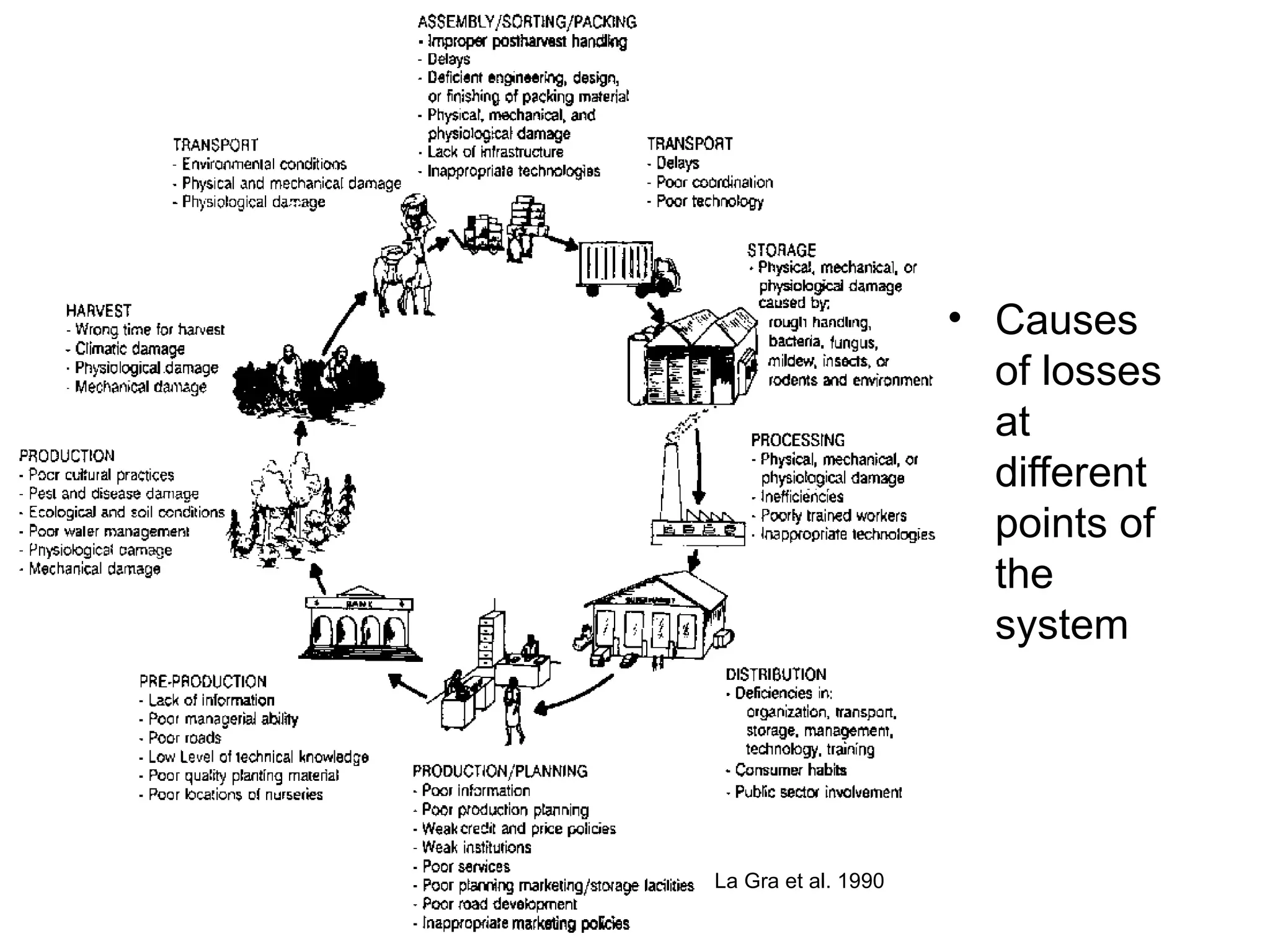

1. Defining postharvest technology and explaining its importance in preventing food losses, improving nutrition, adding value to agricultural products, and generating jobs.

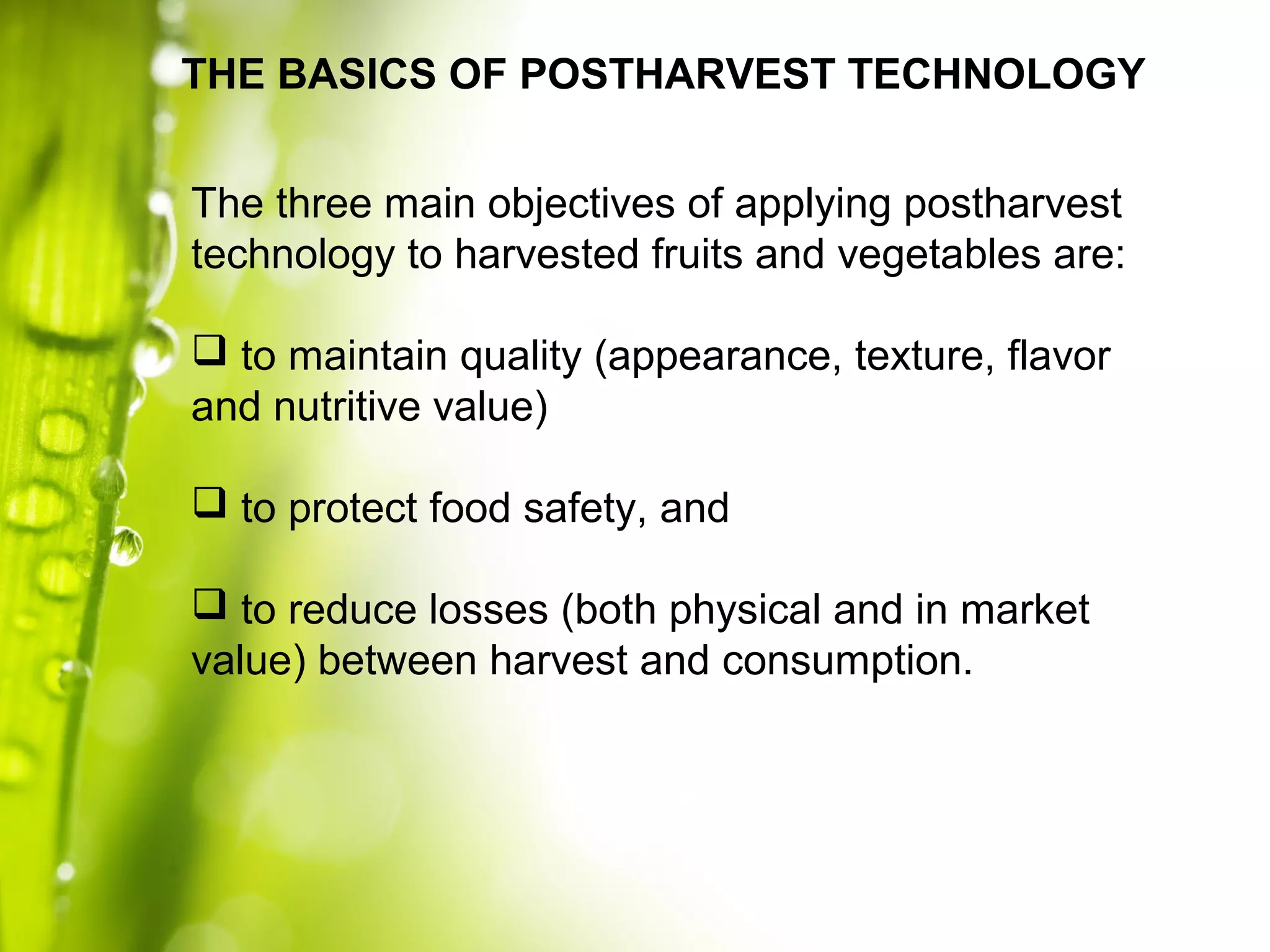

2. The three main objectives of postharvest technology are maintaining quality, protecting food safety, and reducing losses between harvest and consumption.

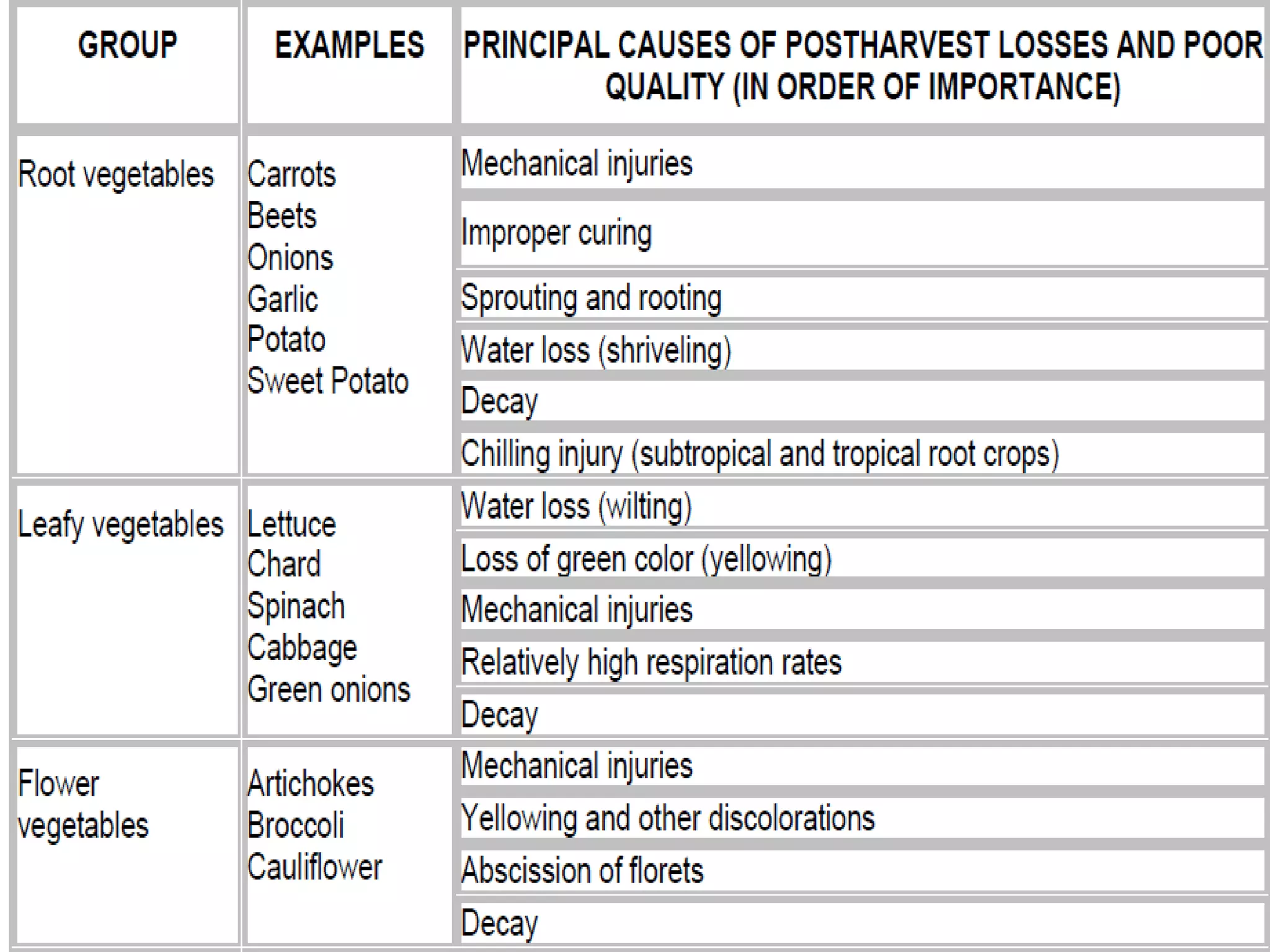

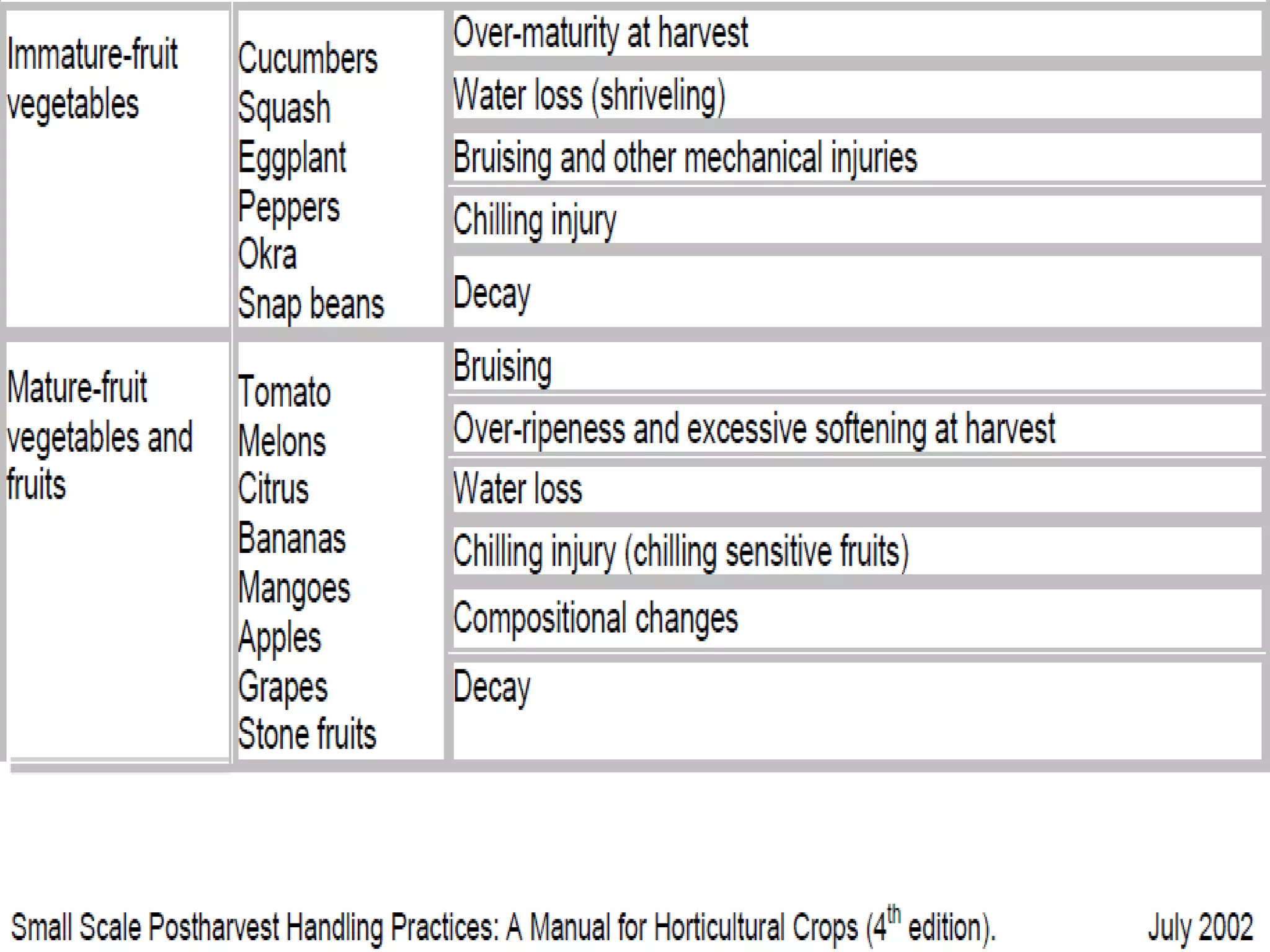

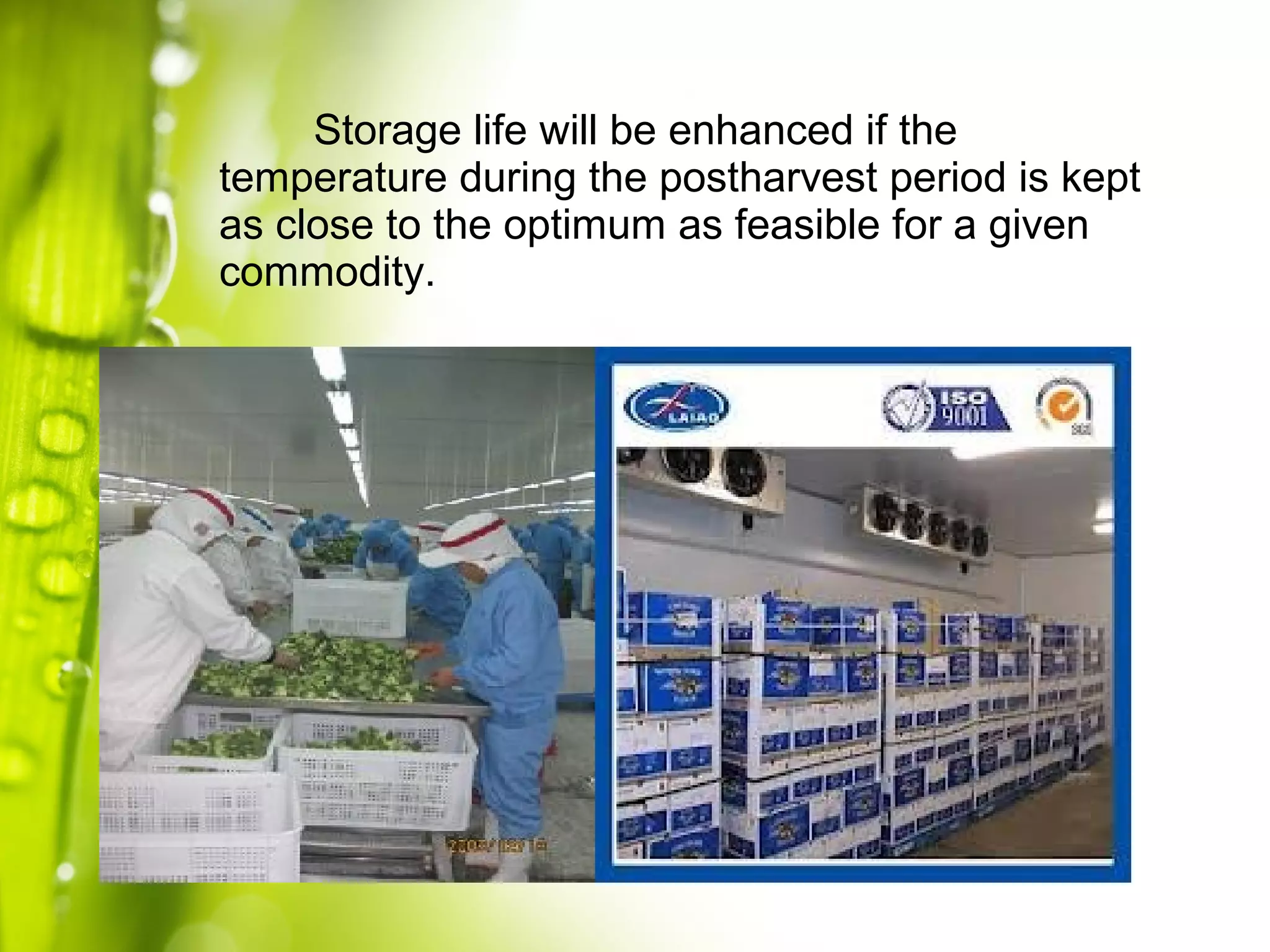

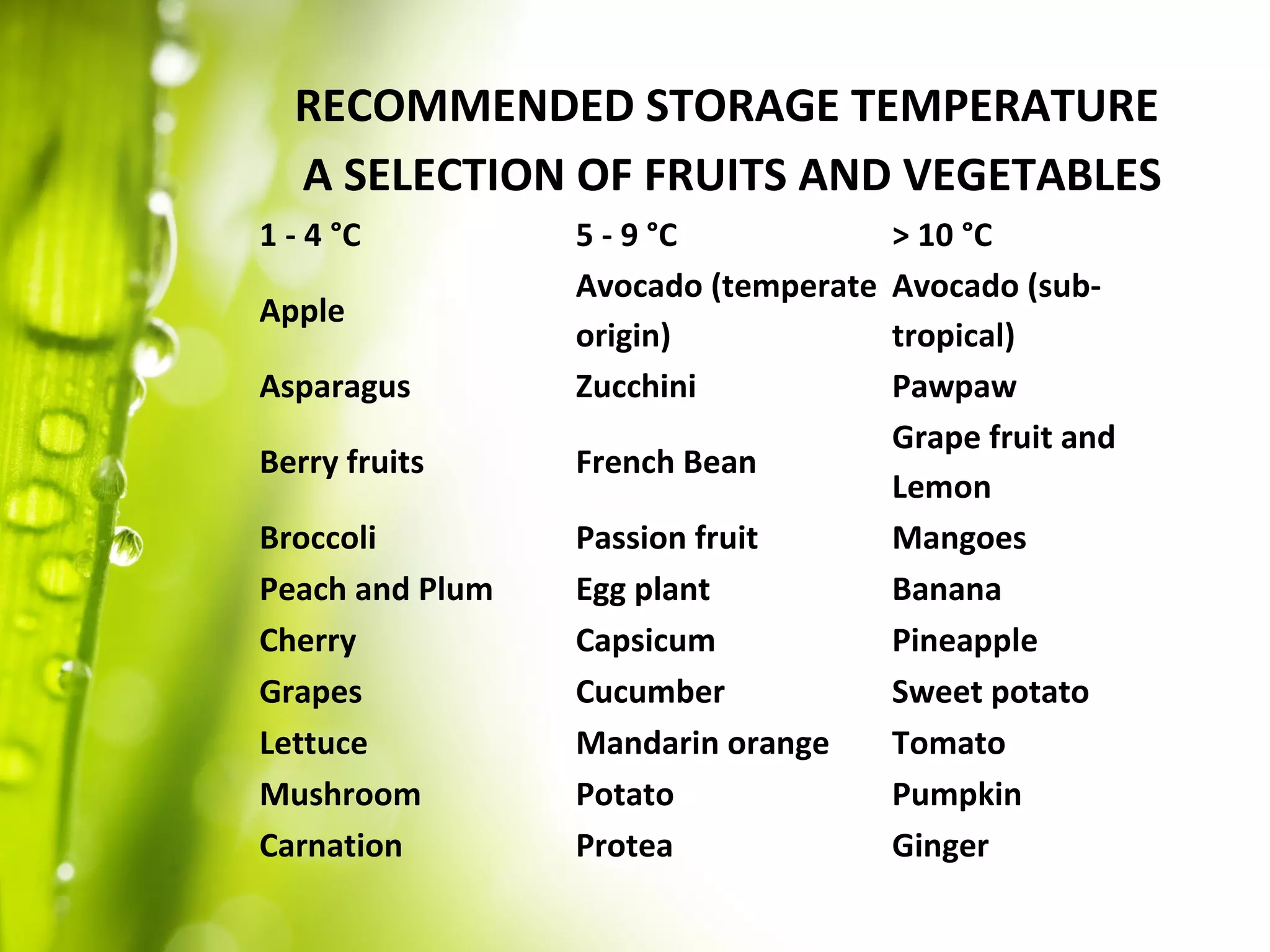

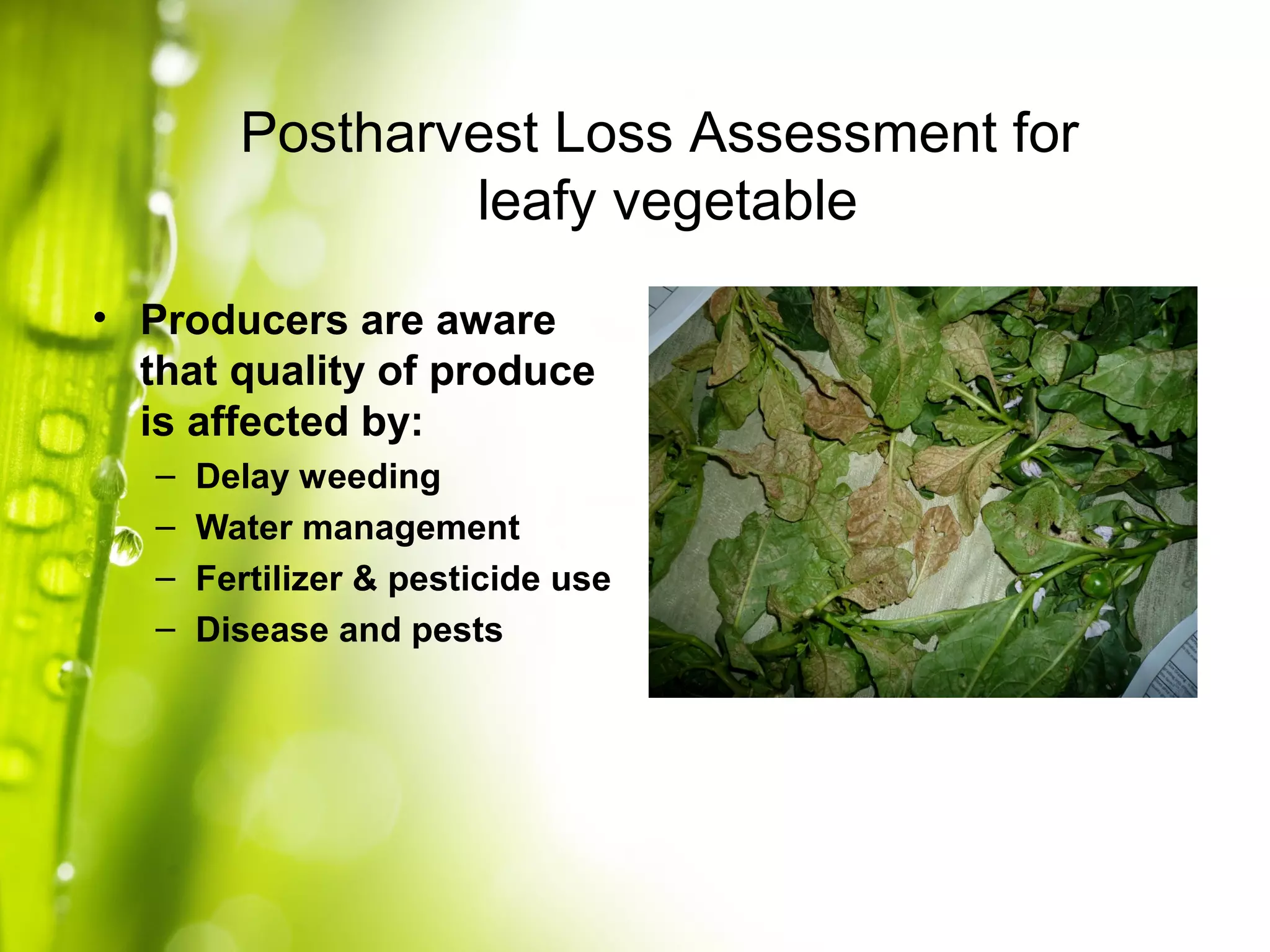

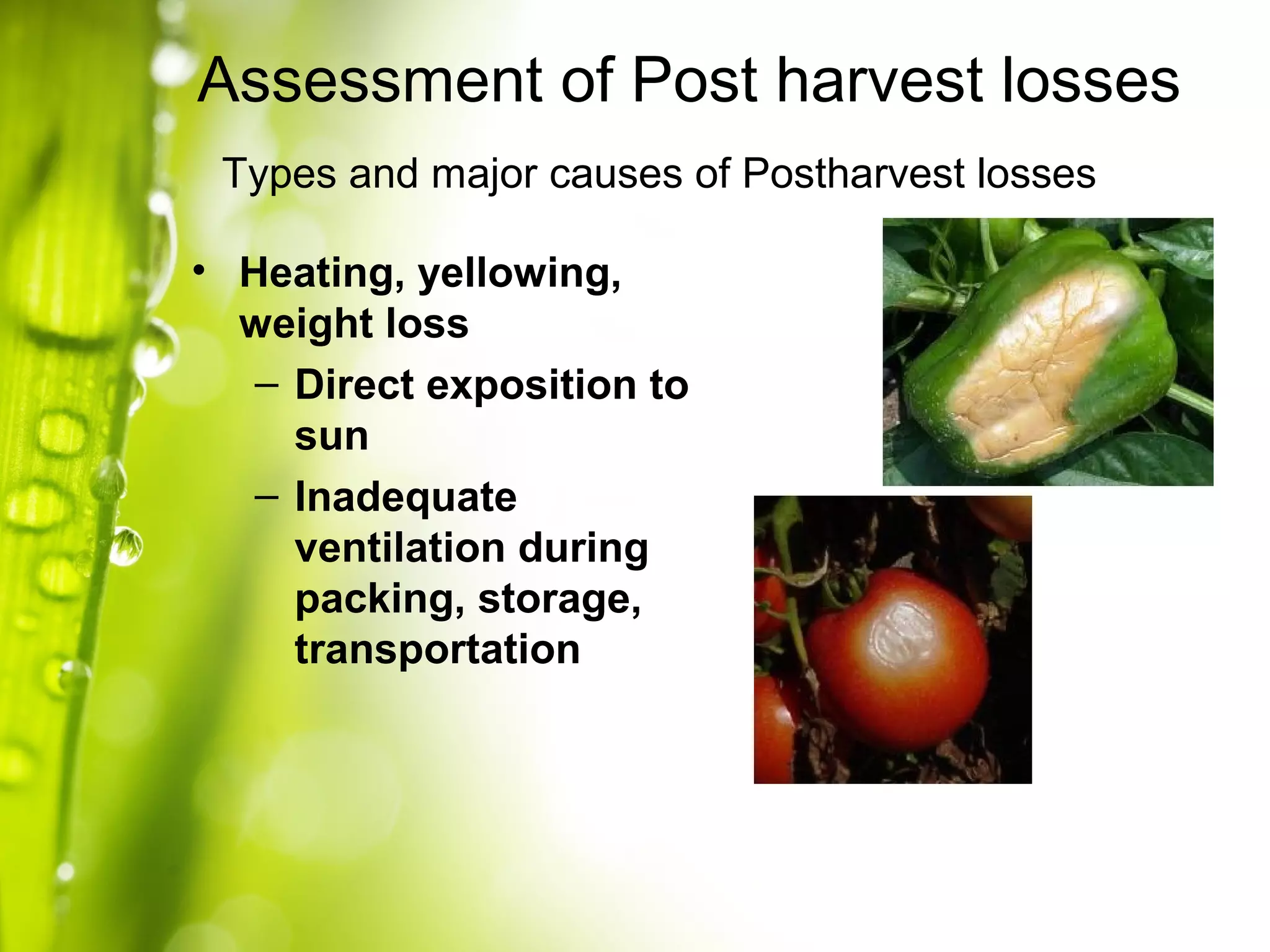

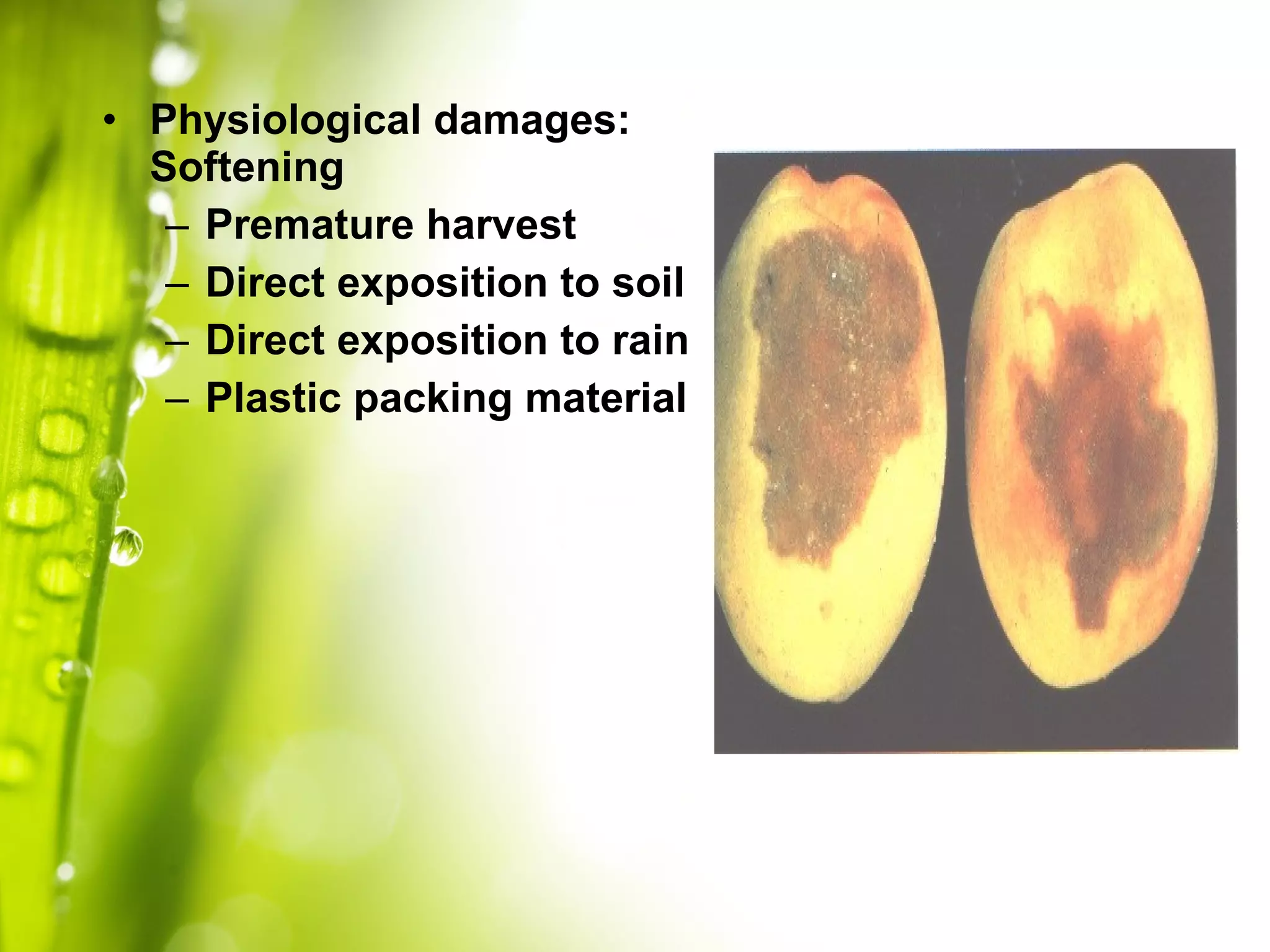

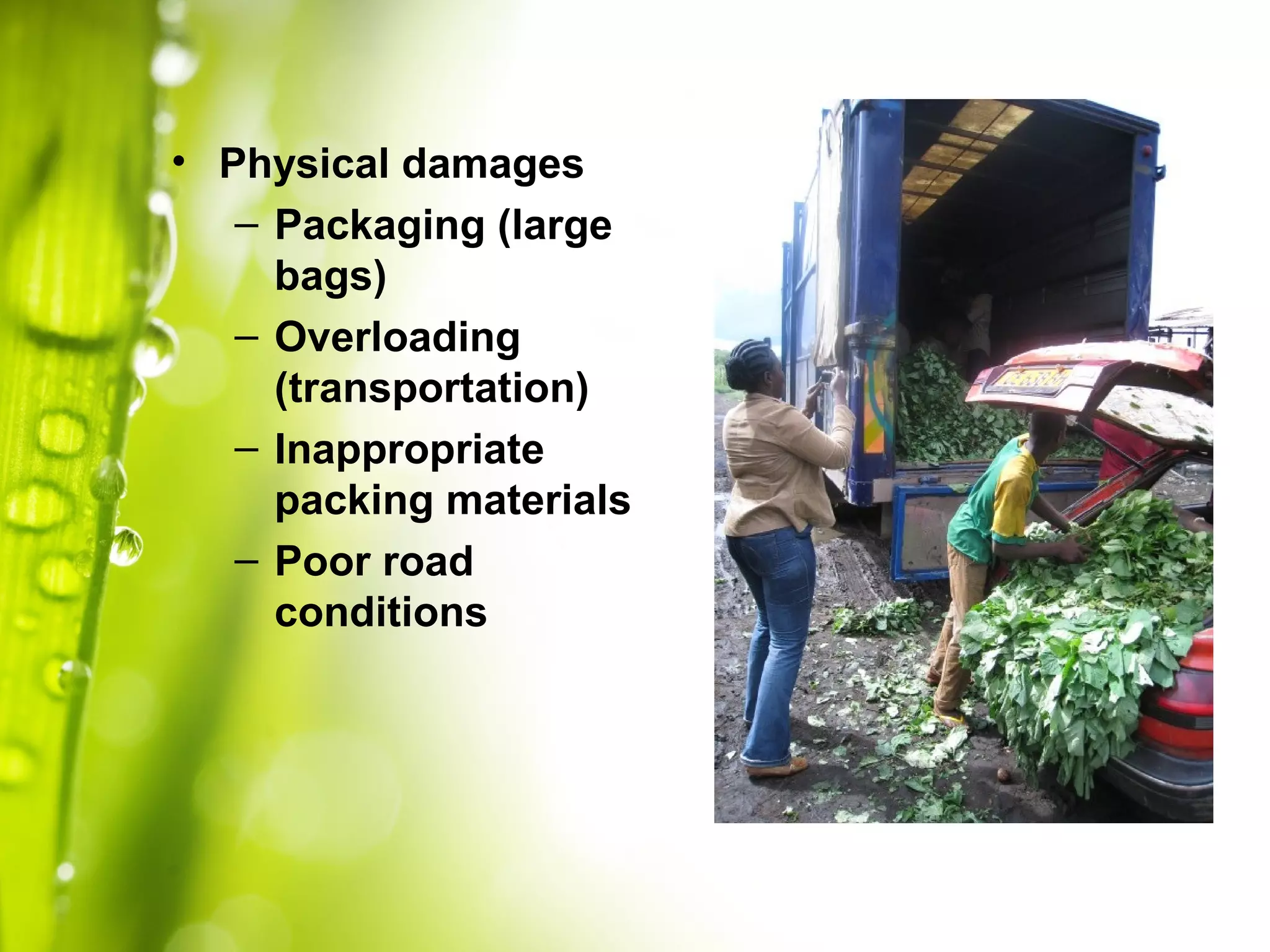

3. Common causes of postharvest losses in the Philippines include rough handling, inadequate cooling and temperature control, lack of sorting, and inadequate packaging. Proper temperature management and reducing damage is key to reducing losses.