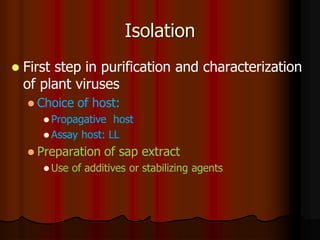

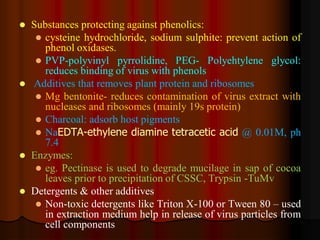

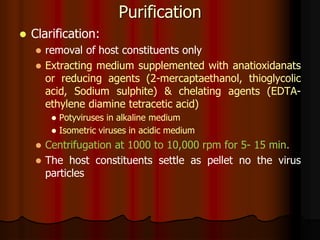

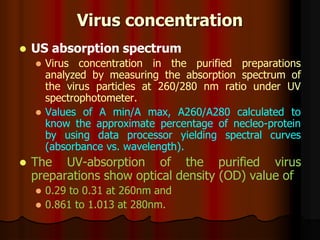

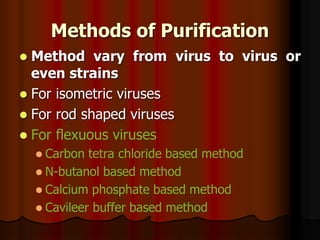

This document discusses methods for isolating, purifying, and characterizing plant viruses. Isolation involves preparing a sap extract from an infected host plant using stabilizing additives. Purification methods include clarification by centrifugation to remove host constituents, concentration through high-speed centrifugation, and final purification using density gradient centrifugation to separate virus particles based on properties like size and density. Characterization involves determining virus concentration using UV absorption spectroscopy and examining virus morphology under microscopy. The goal is to obtain pure virus preparations for studying physical and chemical virus properties.