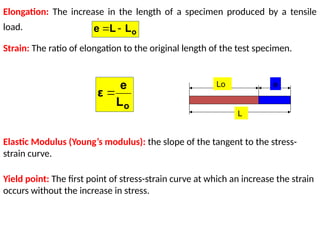

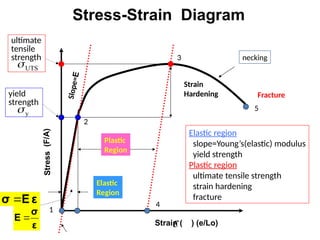

The document outlines various tests for assessing the mechanical properties of materials such as concrete, steel, and timber, including compression, tensile, and flexural tests. It details the procedures for conducting these tests and the significance of mechanical properties like tensile strength and modulus of elasticity for material selection in engineering. Key definitions and equations relevant to stress, strain, and other properties are also provided, highlighting the importance of understanding material behavior under load.