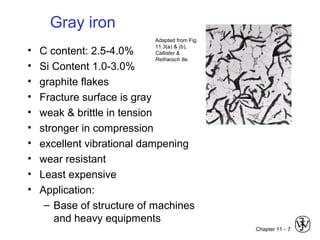

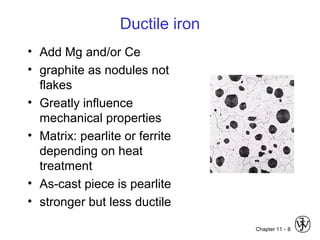

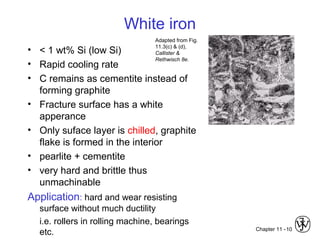

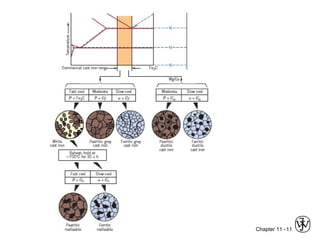

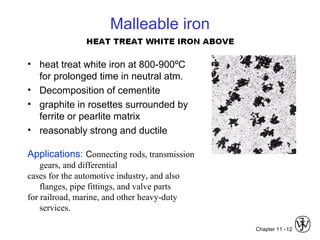

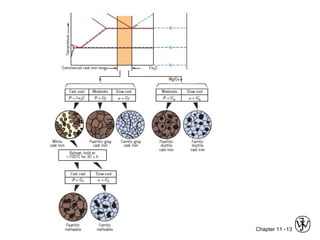

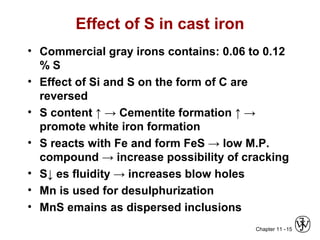

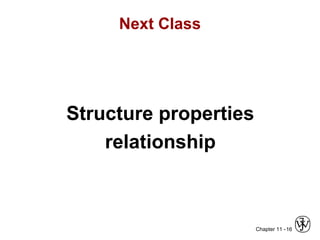

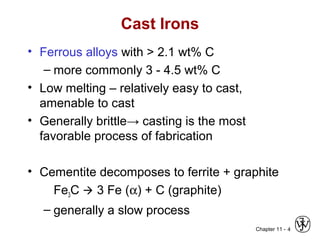

This document discusses types of cast iron and their properties and applications. It covers gray iron, which contains graphite flakes and is strong in compression; ductile iron, which contains graphite nodules and has improved mechanical properties through heat treatment; white iron, which is very hard and brittle; and malleable iron, made by heat treating white iron to form graphite rosettes. Silicon promotes graphite formation while sulfur promotes cementite formation and brittleness. The next class will cover the relationship between structure and properties of cast irons.

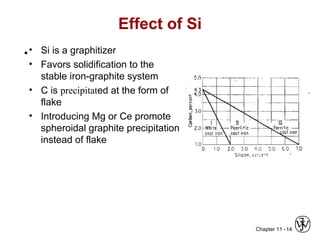

![Chapter 11 - 5

Fe-C True Equilibrium Diagram

Graphite formation

promoted by

• Si > 1 wt%

• slow cooling

Adapted from Fig. 11.2,

Callister & Rethwisch 8e.

[Fig. 11.2 adapted from

Binary Alloy Phase

Diagrams, 2nd ed.,

Vol. 1, T.B. Massalski (Ed.-

in-Chief), ASM International,

Materials Park, OH, 1990.]

1600

1400

1200

1000

800

600

400

0 1 2 3 4 90

L

γ +L

α + Graphite

Liquid +

Graphite

(Fe) C, wt% C

0.65

740ºC

T(ºC)

γ + Graphite

100

1153ºCγ

Austenite 4.2 wt% C

α + γ](https://image.slidesharecdn.com/lec05-150114115107-conversion-gate02/85/Lec-05-5-320.jpg)