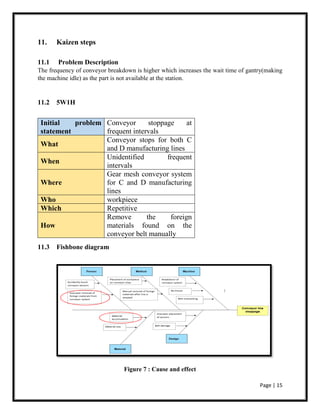

The document is a project report focused on reducing downtime in a manufacturing setting using lean manufacturing principles and tools. It details the analysis of workflow, time studies, and several improvement techniques, such as line balancing and kaizen, aimed at enhancing efficiency and minimizing waste in operations. The findings recommend various solutions to improve gantry performance and address identified issues leading to production delays.