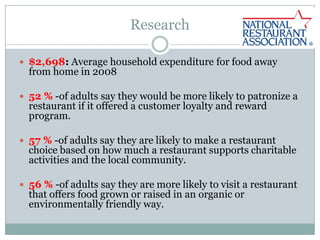

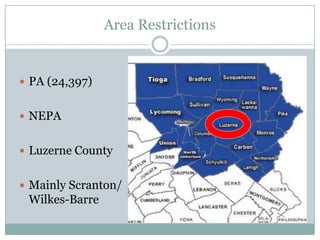

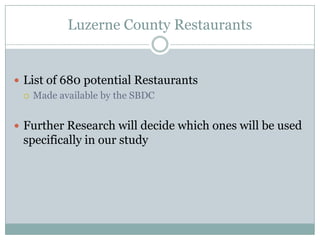

This document summarizes a student research project on applying lean and green operations principles to local restaurants in NEPA. It introduces the group members and advisor for the project. It then provides summaries of what it means to be lean, focusing on eliminating waste, and what it means to be green. Specific lean and green practices that could benefit restaurants are discussed, like reducing overproduction, waiting times, and inventory. The restaurant industry overview provides statistics on its size and importance to the economy. Limitations to implementing changes are noted, like different restaurant sizes and types and targeting specific NEPA businesses.