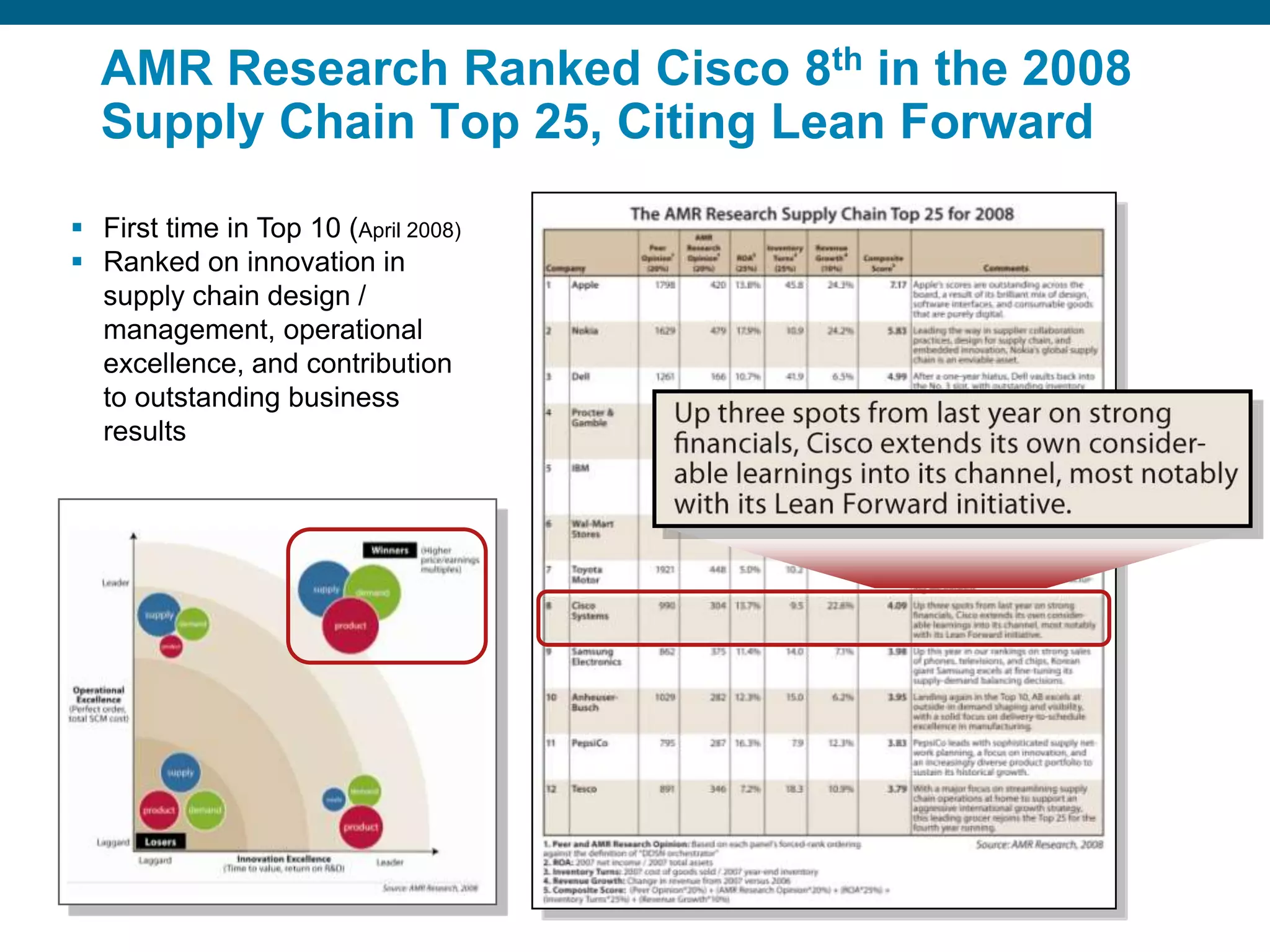

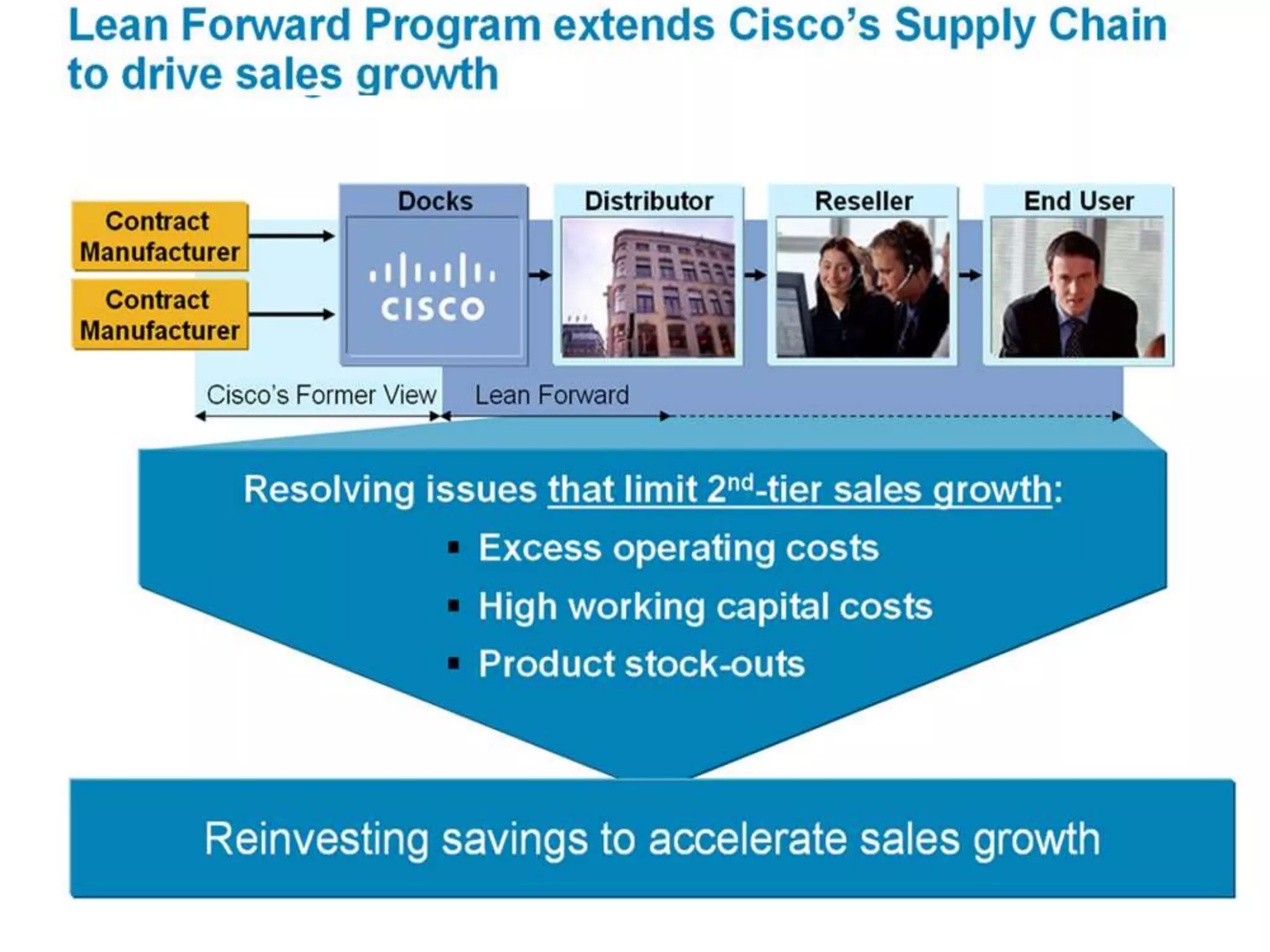

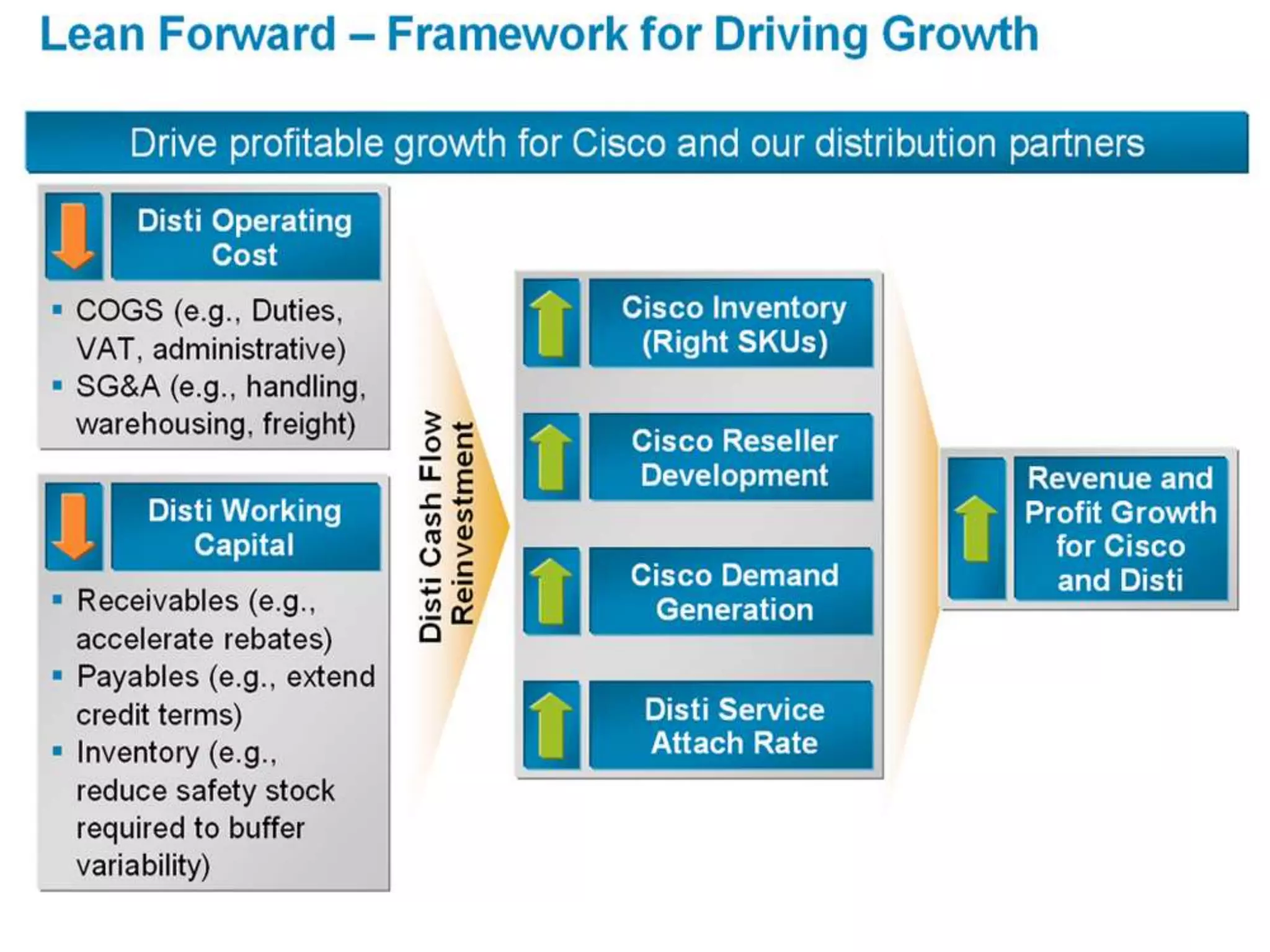

The document discusses Cisco's 'Lean Forward' initiative aimed at enhancing profitable growth and sales acceleration by extending lean manufacturing principles into its distribution channels. It identifies challenges such as high operating costs and unpredictable lead times, and outlines a collaborative framework involving supply chain management and various stakeholders. Key benefits include improved supply chain visibility, streamlined processes, and mutual profitability for Cisco and its distributors.