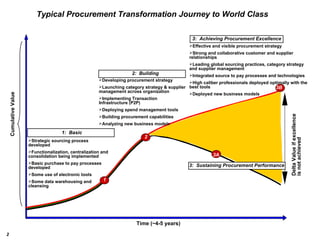

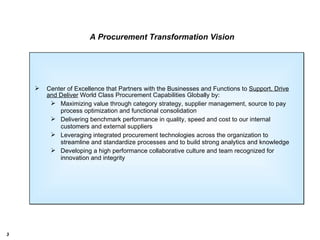

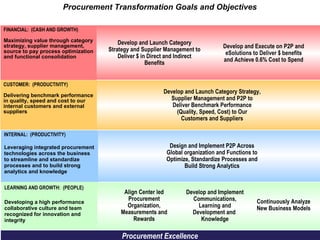

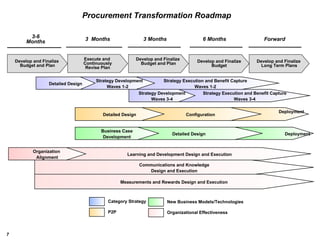

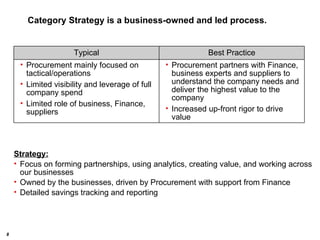

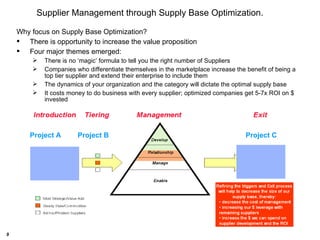

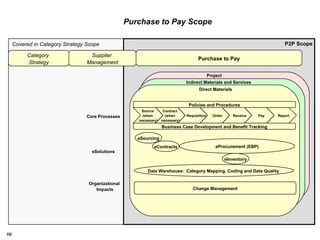

The document outlines a typical procurement transformation journey from basic functionalization to achieving procurement excellence. It involves developing strategic sourcing processes, category strategies, and integrated source-to-pay processes and technologies over 4-5 years. The vision is to establish a center of excellence that delivers world-class procurement capabilities by maximizing value, delivering benchmark performance, leveraging technologies, and developing a high-performing team.