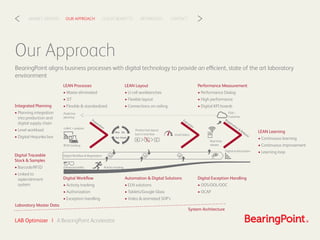

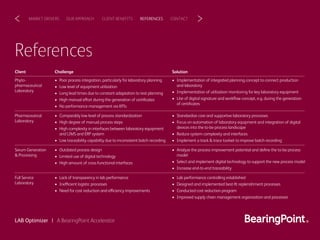

The document describes BearingPoint's LAB Optimizer accelerator which helps laboratories connect lean processes with digital technologies. It provides an end-to-end approach along the laboratory value chain from planning and sample management to test data processing and certificate creation. This allows laboratories to unlock their potential and achieve cost efficiency, compliance and transparency. The approach involves aligning business processes with digital tools like automation, master data systems and digital workflows. This provides an efficient modern laboratory environment.