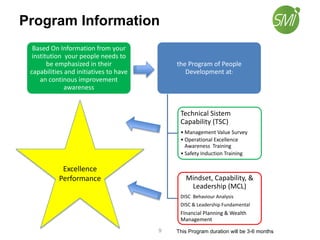

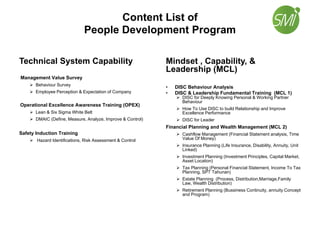

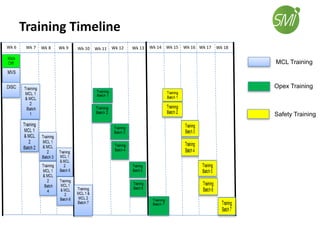

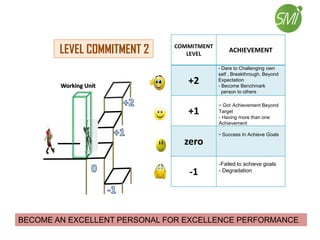

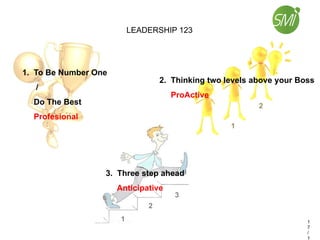

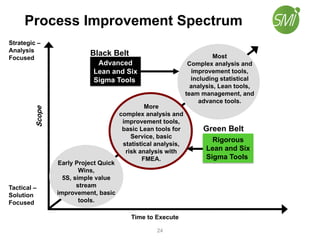

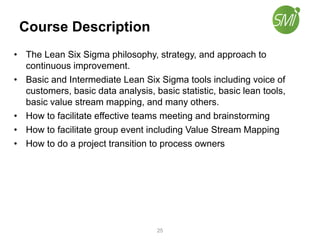

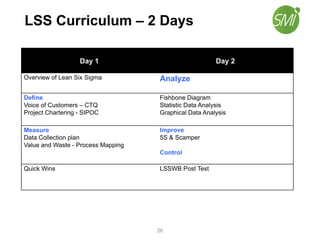

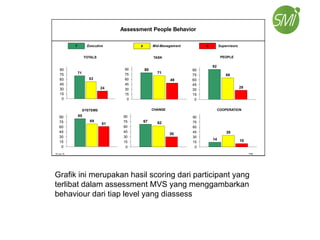

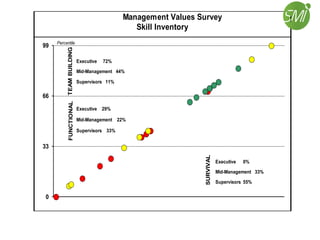

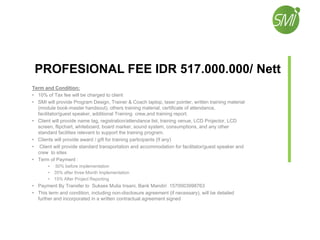

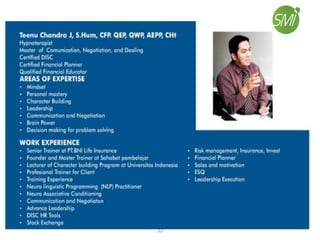

This document outlines a people capability development program focused on continuous improvement. It discusses why the company SMI should be partnered with to provide the program. The program includes technical system capability training, such as management value surveys and operational excellence awareness training. It also includes mindset, capability, and leadership training covering topics like DISC behavior analysis and financial planning. A timeline shows the training will occur over 3-6 months. Trainer profiles are provided for Ferdinand Hasioholan and Arden Djapri, who have experience implementing continuous improvement programs. The fee for the program is outlined.