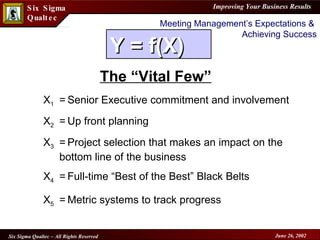

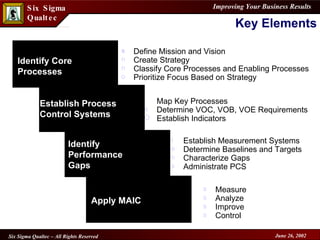

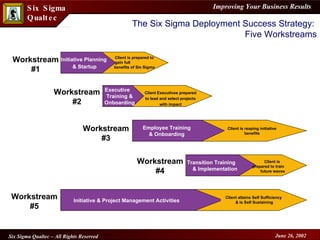

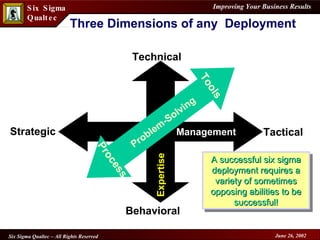

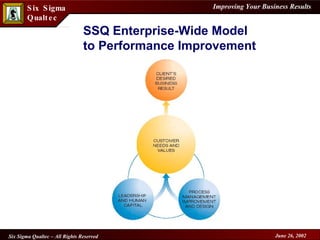

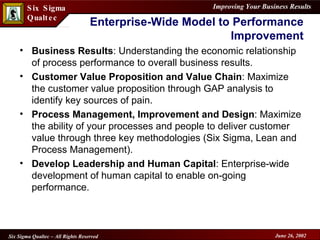

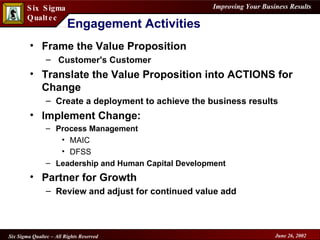

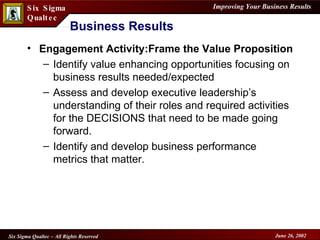

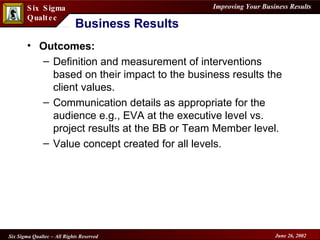

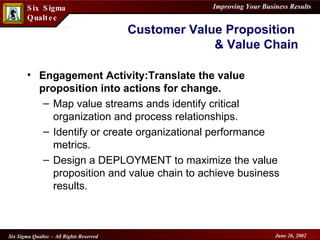

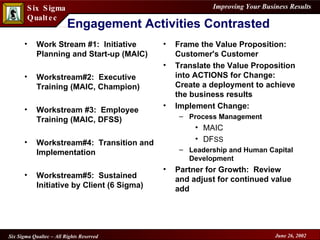

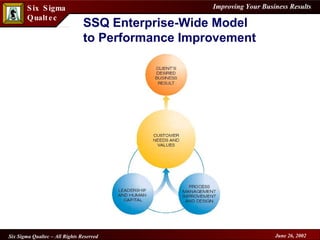

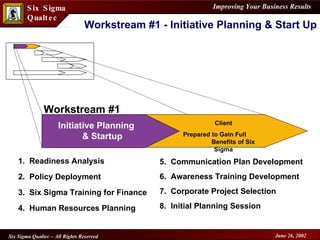

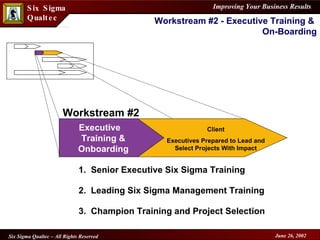

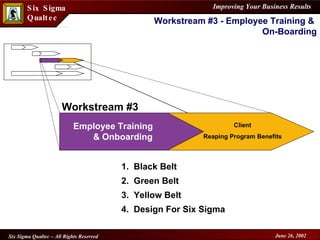

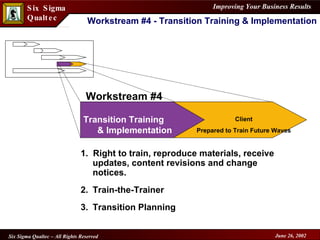

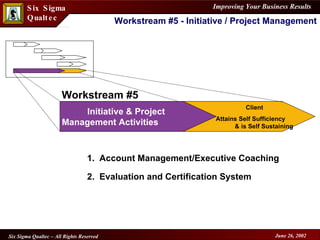

This document discusses a holistic approach to improving business results through Six Sigma that goes beyond traditional Six Sigma deployments. It presents a five workstream model for deploying Six Sigma enterprise-wide that includes initiative planning, executive training, employee training, transitioning to client self-sufficiency, and ongoing initiative and project management. The key is aligning Six Sigma efforts with business objectives and developing leadership and human capital across the organization to sustain improvements.