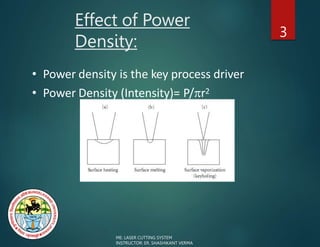

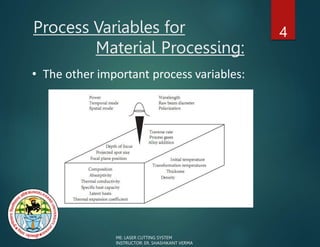

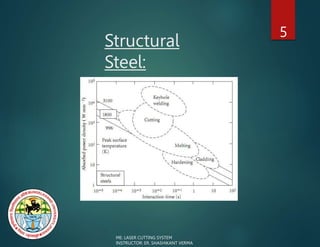

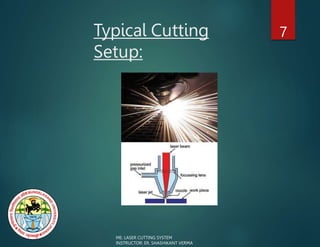

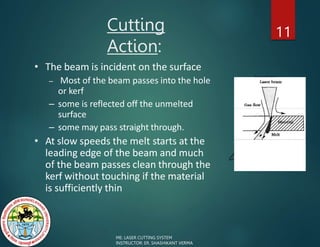

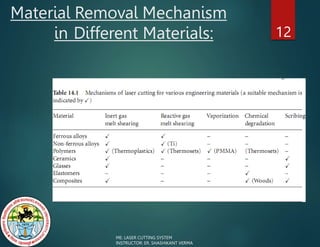

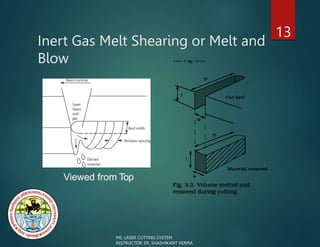

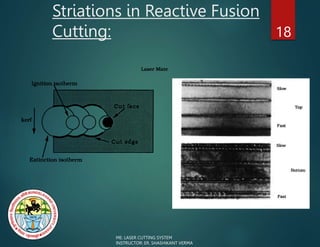

The document discusses the process of laser cutting. It describes the key parameters that affect laser cutting like power density, process variables for different materials, and typical cutting setups. It explains the different mechanisms of laser cutting such as melting, vaporization, and controlled fracture. Factors like spot size, wavelength and their effects on cutting are also summarized.