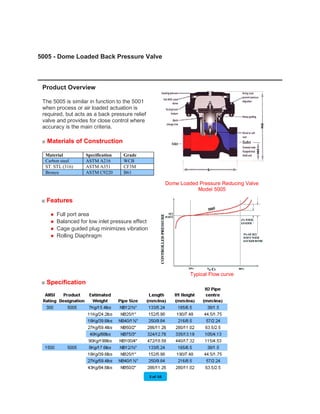

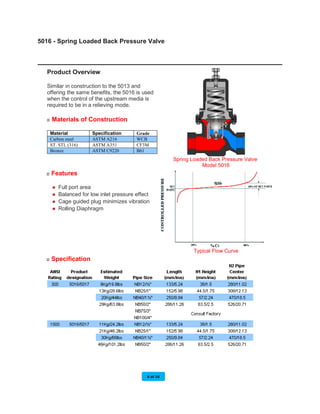

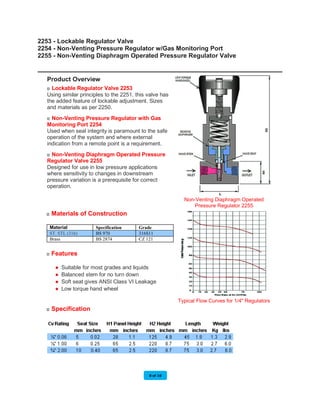

The document details the features and specifications of the Dycon series 5000 and 2000 regulator control valves, including materials, pressure ratings, and various model applications. It highlights unique designs that facilitate multiple control modes, suitable for offshore, petrochemical, and industrial applications. The series offers a range of valve options, such as dome and spring-loaded configurations, that cater to different media and pressure control needs.