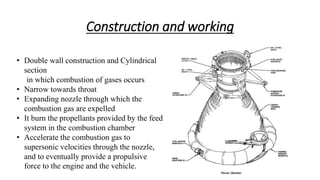

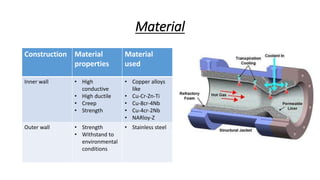

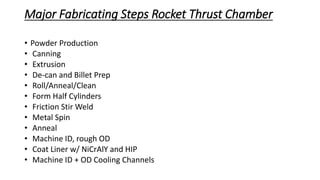

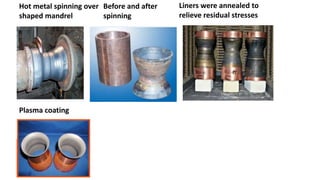

The document discusses the design and construction of rocket thrust chamber bodies. It describes how rocket thrust chambers must withstand extreme temperatures and pressures during combustion. They are typically constructed of double-walled cylinders with inner walls made of high-conductivity and high-strength copper alloys to withstand the heat, and outer walls made of stainless steel. The document outlines the major fabrication steps involving powder production, forming cylinders, welding, machining, and coating the inner wall with protective materials. It also discusses the material properties and applications of rocket thrust chambers.