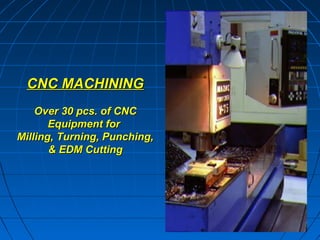

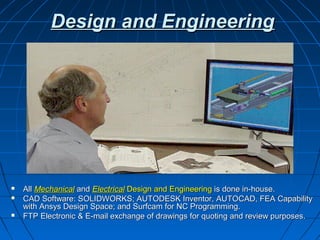

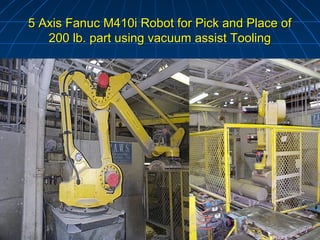

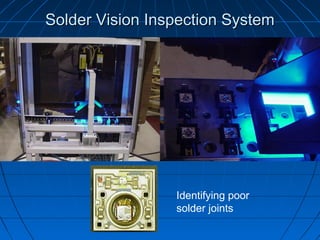

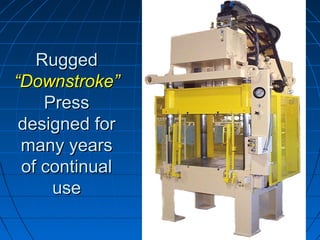

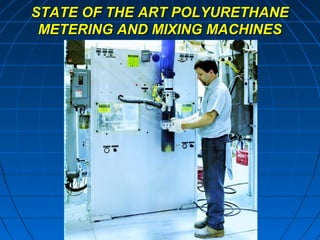

Tool & Die Inc. is a manufacturing company located in Olean, NY that was founded in 1965. They provide capabilities such as mechanical and electrical design, robotics, special machinery, hydraulic presses, CNC machining, tooling and fixtures, sheet metal work, casting and molding of polymers, and quality control. They have a large machine shop with over 30 CNC machines for milling, turning, punching and EDM cutting. They specialize in building custom automated machinery and have experience in industries such as automotive, aerospace, and defense.