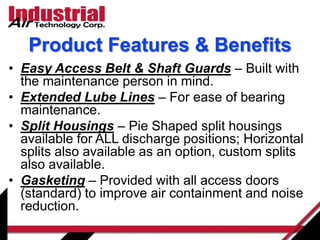

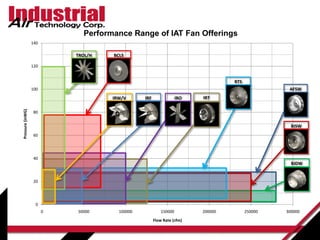

This document provides information about Industrial Air Technology Corp (IATC), a manufacturer of centrifugal fans and blowers. It lists the industries IATC serves, engineering support offered, product lines including airfoil, backward inclined, industrial exhauster, and high pressure blower series, motor and drive options, accessories, and the information needed for IATC to provide a quote.